Welcome to the official website of Luoyang AISITE Transformer Co., LTD

The comparison between dry-type transformers and oil immersed transformers

Release time:

Apr 14,2025

Source:

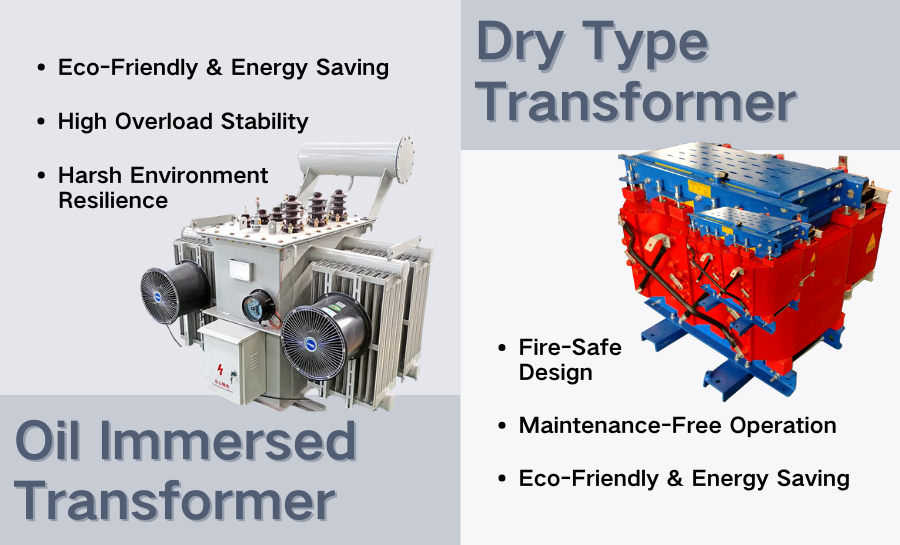

To help clients better understand the differences between dry-type transformers and oil immersed transformers and then choose the right type used for the special application scenarios, the article will explain the characteristics about dry-type and oil immersed transformers in detail.

*Structure and Materials

Dry-type transformer: Usually solid insulating materials such as epoxy resin are used to cast or impregnate the windings to achieve electrical insulation and mechanical support. There is no oil tank or transformer oil. The iron core is generally made of high-quality silicon steel sheets.

Oil-immersed transformer: It consists of iron core, winding, oil tank, oil pillow and other components. The windings are immersed in transformer oil and rely on oil for insulation and heat dissipation.

*Type of cooling

Dry-type transformer: air cooling, relatively poor heat dissipation effect, and inferior overload capacity to oil-immersed transformers. However, it has good electrical insulation performance and mechanical strength, and can withstand higher short-circuit currents.

Oil-immersed transformer: oil circulation cooling, good heat dissipation performance, and strong overload capacity. However, oil-immersed transformers will generate certain noise during operation.

*Maintenance and cost

Dry-type transformer: simple maintenance, no need to regularly check and replace transformer oil, only regular appearance inspection and electrical performance test are required. However, the initial investment cost is high.

Oil-immersed transformer: regular inspection of transformer oil quality and oil level, as well as maintenance work such as oil filtering and oil replacement are required, and the maintenance cost is relatively high. However, in large-capacity and high-voltage applications, its unit capacity cost is usually lower than that of dry-type transformers.

*Application and Scenarios

Oil-immersed transformers are generally installed in separate transformer rooms or outdoors due to fire protection requirements, while dry-type transformers must be installed indoors, generally in low-voltage distribution rooms, and installed side by side with low-voltage distribution cabinets.

Dry transformers are required in complex buildings (basements, floors, rooftops, etc.) and crowded places. Oil transformers are used in independent substations. Dry transformers are generally used in box transformers. Oil transformers are generally used for temporary outdoor power supply. During construction, dry transformers and oil transformers are selected according to the space. Oil transformers can be selected when the space is large, and dry transformers can be selected when the space is crowded.

Oil transformers are easy to use in areas with relatively humid and hot climates. If dry transformers are used, they must be equipped with forced air cooling equipment.

*Strength and Weakness

Each type of transformer has its advantages and disadvantages. For example, oil-immersed transformers are low-cost and easy to maintain, but they are flammable and explosive. Dry-type transformers have good fire resistance and can be installed in the load center area to reduce voltage loss and power loss, but they are expensive, large in size, poor in moisture and dust resistance, and noisy. In addition, dry-type transformers also have the advantages of easy disassembly and transportation, easy cleaning and maintenance, no need for a base for installation, and no oil seepage pool.

*How to choose

The article will give you some recommendations about how to choose the right transformers according to your usage and requirements.

It is recommended to choose dry-type transformers in the following situations

Places with high safety requirements: Places with dense population and extremely high safety requirements such as hospitals, schools, and kindergartens. Once a fire occurs, the consequences will be disastrous. Dry-type transformers do not use flammable oil as insulation and cooling medium, which can effectively reduce the risk of fire and ensure the safety of personnel and equipment. There are also data centers, which store a large amount of important data and equipment and have strict requirements for fire and explosion prevention. Dry-type transformers are an ideal choice.

Indoor spaces with relatively harsh environments: In some indoor environments with humidity, dust or corrosive gases, dry-type transformers have better adaptability. For example, in underground parking lots, industrial plants and other places, dry-type transformers can effectively avoid insulation performance degradation and equipment damage caused by environmental factors by strengthening insulation and protective measures.

Places with strict noise restrictions: Dry-type transformers have relatively low noise during operation and are suitable for use in places with high noise requirements, such as residential areas, hotels, office buildings, etc. These places need to create a quiet environment, and dry-type transformers can meet this requirement.

It is recommended to choose oil-immersed transformers in the following cases

Large power systems: In large power systems such as power plants and substations, a large amount of electric energy needs to be transmitted and distributed. Oil-immersed transformers have the advantages of large capacity and high voltage level, which can meet the needs of power systems. For example, in ultra-high voltage transmission systems of 500kV and above, oil-immersed transformers are one of the main equipment.

Outdoor open space: Oil-immersed transformers are suitable for installation in open outdoor places, such as substations in the suburbs. In these places, the fire protection requirements are relatively low, and there is enough space to install and maintain equipment. At the same time, the outdoor environment is conducive to the heat dissipation of oil-immersed transformers, which can give full play to their good heat dissipation performance.

Cost-sensitive scenarios: The manufacturing cost of oil-immersed transformers is relatively low. For some projects that are more cost-sensitive, such as some small factories, rural power grid transformation, etc., if the requirements for fire protection and explosion protection are not high, choosing oil-immersed transformers can reduce investment costs.

As a professional manufacturer of power transformers, with 15 years’ experience and abundant cases of exporting, if there is any question about power transformers, welcome to contact us at any time. We will provide you with prompt answer and best service.

keyword:

RELATED NEWS