Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Transformer Manufacturing Process and Future Trends: Innovation and Efficiency

Release time:

Sep 01,2025

Source:

Transformers, as essential core equipment in the construction and development of power systems, come in a wide variety of types, including dry-type transformers, oil-immersed transformers, high- and low-voltage switchgear, American-style box transformers, and specialized transformers. The widespread use of these transformers provides strong support for the stable operation of power systems. This article will delve into the transformer production process and the impact of new materials on production processes, comprehensively analyzing all aspects of the transformer production process.

Transformer Production Process

Transformer production encompasses multiple stages, including rigorous testing to ensure quality and performance. Transformer production encompasses several key steps, including the meticulous fabrication of the core and insulation, winding assembly, and the meticulous construction of clamps, fasteners, and fuel tanks. Rigorous testing is required at each step to ensure product quality and performance. Of particular note, metal sheets and profiles undergo meticulous rust removal treatments such as spraying and polishing before cutting. The application of anti-rust paint and topcoat is also essential during the manufacturing of fuel tanks and conservators. These steps enhance the transformer's corrosion resistance.

1. Optimization of the Core Manufacturing Process

The multi-stage jointing process reduces noise and no-load losses, improving core quality. The key to improving core manufacturing lies in improving the quality and usage of cutting equipment. Multi-stage jointing has become the mainstream in core production. Advances in transformer design have effectively addressed losses at core joints. In the past, a single jointing process was the primary method, but now, multi-stage jointing is widely used in manufacturing, with some companies even adopting partial step jointing.

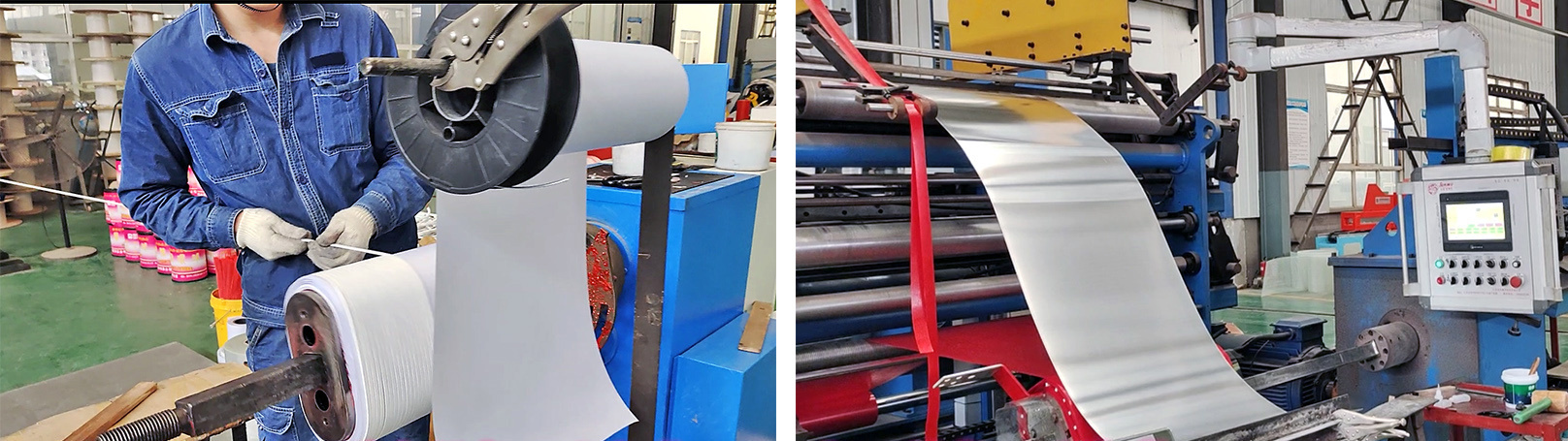

2. Insulation Manufacturing Process

Insulation materials are rigorously re-inspected, and insulation components are manufactured through precise cutting and hot pressing. The first step in the insulation component production process is a rigorous quality inspection of the insulation material to ensure it meets applicable standards. Subsequently, precise cutting is performed according to a pre-designed cutout plan. After cutting, the cardboard is glued and stacked, and then hot-pressed using steam hot pressing.

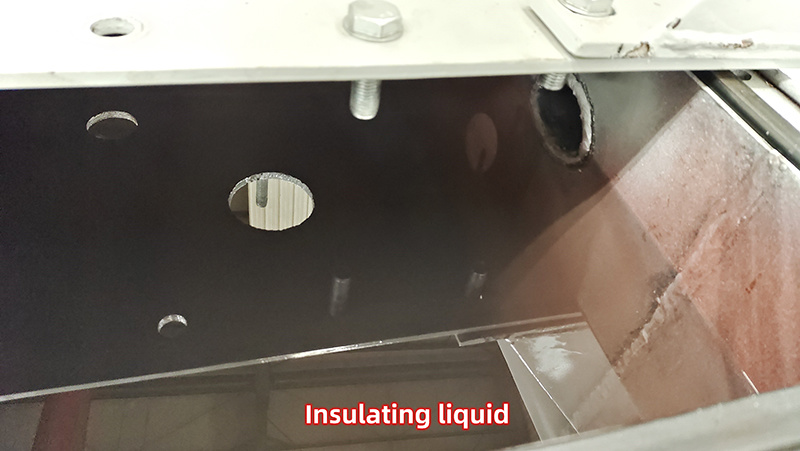

3. Insulation Drying and Oil Treatment Process

Vapor-phase drying has become a widely adopted advanced process in oil-immersed transformer manufacturing. Compared to traditional vacuum dehydration techniques, it significantly improves drying efficiency and optimizes insulation system quality.

Since its global adoption in the 1980s, vapor-phase drying technology has gained widespread recognition for its ability to efficiently remove moisture and maintain the dielectric strength of insulation materials. In recent years, system designs such as integrated kerosene evaporators have further improved the energy efficiency and compactness of equipment.

When combined with modern vacuum oil filtration and degassing systems, this drying process produces transformers with higher reliability and longer service life. The entire process complies with international standards and ensures stable operation under diverse environmental conditions.

4. Winding and Shaping Process

Selecting winding equipment and materials optimizes winding structure to enhance short-circuit resistance. Winding and shaping are critical steps in transformer manufacturing. First, it is necessary to select the appropriate winding equipment to meet specific requirements. Furthermore, the selection of winding molds is also crucial. By adopting advanced coil shaping processes, the clearance between the coil and the core can be reduced, resulting in a more compact product structure.

5. Welding Parts Fabrication

Rust removal followed by welding enhances product durability and safety. Welding parts fabrication is an essential step in transformer manufacturing. First, carefully select the sheet metal and profiles and rigorously remove rust. After quality assurance inspection, cutting and welding can begin.

6. Assembly Process

Strictly control the core geometry and dimensions to improve production efficiency. The transformer assembly process typically consists of two stages: pre-furnace body assembly and post-furnace final assembly. During core assembly, strict control of core geometry and dimensions is crucial to ensure that the core's axis, thickness, and design meet requirements. A reasonable fill factor is also a key factor in improving overall core quality.

7. Vacuum Oil Filling Process

The vacuum oil filling process operates differently for large and small transformers. Small distribution transformers also follow the vacuum oil filling process, but because their oil tanks cannot withstand vacuum pressure, they require vacuum oil filling tanks designed specifically for small transformers.

Transformer Development Trends

Application of New Materials in Transformer Manufacturing

The use of amorphous alloy materials in transformers improves energy efficiency and cost-effectiveness. With the continuous advancement of the power industry, traditional high-energy-consumption transformers are no longer able to meet the demands of modern power transmission. Therefore, in-depth research is needed on transformer manufacturing materials to enhance their environmental and energy-saving characteristics. Key to this process is in-depth analysis of the performance of new materials. For example, widely used amorphous alloy transformers have attracted widespread attention for their excellent energy efficiency, cost-effectiveness, and low no-load losses. These new transformers offer particularly significant energy-saving benefits in rural and remote mountainous areas. By incorporating amorphous alloy materials into the transformer core, no-load losses can be significantly reduced, improving performance.

Energy Saving and Intelligence

Transformers are evolving towards energy efficiency, high impedance, and intelligence. Energy efficiency has become a key factor in transformers, and transformers with high impedance and explosion-proof properties are widely used in both rural and urban power grids. Furthermore, with increasing levels of intelligence, transformer operation will become even simpler, enabling remote monitoring and operation.

In the future, transformer production processes will increasingly become more environmentally friendly and energy-efficient, while operating noise levels will be further reduced, and the degree of integration and reliability will be enhanced. During the manufacturing process, we must increase the application of new materials and processes, and implement strict management to ensure that every step of transformer manufacturing complies with process procedures and requirements. Furthermore, improving the overall quality of transformers and enhancing their environmental and energy-saving performance is crucial to promoting the healthy development of the transformer manufacturing industry.

Exploring more advanced transformer solutions? Contact us for professional technical information and customized support.

📧 Email: [sale@aisite-ast.com]

📞 Phone/Whatsapp: [+86 15896663407]

🌐 Website: [https://www.aisite-ast.com/]

keyword:

RELATED NEWS