Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Metallurgical Industry-Furnace Transformers

Characteristics of the metallurgical industry and its requirements for transfromers

The metallurgical industry is a traditional energy-consuming industry, and its electrical equipment has the characteristics of large capacity, large load impact, and high degree of automation.

During the operation of the equipment, the system voltage is prone to fluctuations and flickering, and short-circuit-like operating conditions frequently occur, the three-phase is unbalanced, and a large number of nonlinear loads (such as arc furnaces, medium-frequency furnaces, rolling mills, etc.) are working. The working current is seriously distorted, and it is easy to generate a large number of harmonics, which endangers the safe operation of the power system and electrical equipment.

The operating environment is relatively harsh, with heavy dust, strong vibration, large temperature changes, and 24-hour uninterrupted operation. Therefore, the reliability of power equipment is higher than that of other industries. In view of the characteristics of the industry, AISITE applies its mature transformer technology to the metallurgical industry.

the Categories of Industrial furnace transformers

This transformer is specially designed to provide power for various electric furnaces. Industrial electric furnace transformers can be roughly divided into three categories: resistance furnace transformers, arc furnace transformers and induction furnace transformers.

Resistance furnace transformer: resistance furnace and salt bath furnace used for heating mechanical parts, heat treatment, powder metallurgy sintering, non-ferrous metal smelting, etc. Because the resistance of the heating element is too small, or the resistance of the heating element changes too much during the heating process, a resistance furnace transformer needs to be equipped between the furnace and the power grid to reduce and adjust the input voltage of the electric furnace.

Arc furnace transformer: It is a special transformer used to power the arc furnace used for steel smelting. It has large capacity, complex structure and high technical requirements. Its secondary voltage is low, generally ranging from tens of volts to hundreds of volts, and it is required to be adjustable within a large range; the secondary current often reaches thousands to tens of thousands of amperes.

Induction furnace transformer: used to power the induction furnace. The induction furnace is an electric furnace that uses the principle of electromagnetic induction to generate an induced current in the metal charge, thereby heating and melting the charge. The induction furnace transformer needs to provide appropriate voltage and frequency to meet the working requirements of the induction furnace.

Applicable Scenarios

Electric furnace transformer products are widely used in a variety of scenarios.

In the field of metal smelting, it covers smelting furnaces for steel, copper, aluminum, etc.;

in ferroalloy production, it helps the manufacture of ferrosilicon, ferromanganese, etc.; and provides reliable electricity for industrial silicon manufacturing.

In calcium carbide production, it ensures stable power supply, and it is also used in the electric heating part of glass melting furnaces in glass manufacturing.

In scientific research experiments, experimental conditions can be precisely controlled.

Special material processing, such as high-temperature ceramic material firing, and waste treatment, can meet the specific power needs of different scenarios.

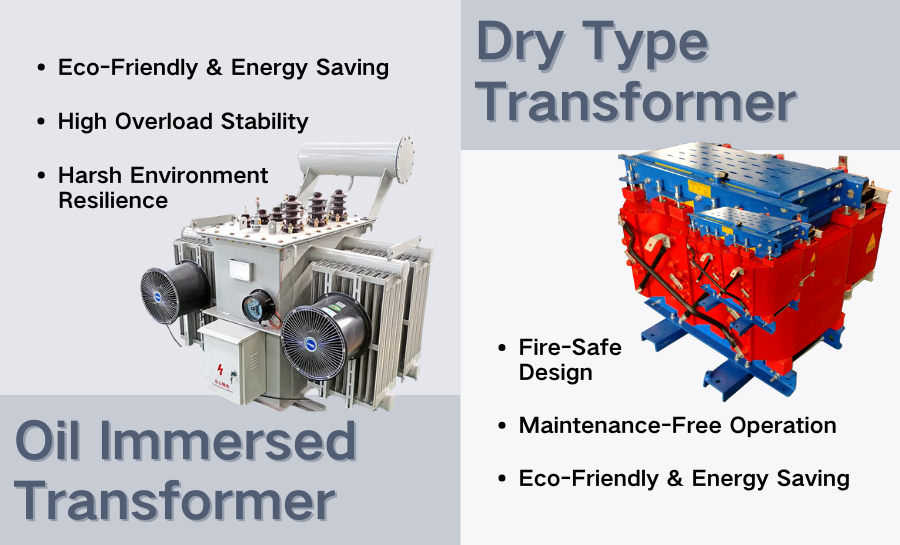

According to the different insulating media, it can be divided into oil-immersed type and dry type.

For more detailed information. pls click here.AISITE Product Catalog(1).pdf

Advanced technology and exquisite craftsmanship

Our portfolio allows utilities, industries, and infrastructure sectors to maximize return on transformer assets by ensuring high reliability and optimized performance while lowering life-cycle costs and environmental impact.