Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Demystifying Transformer Windings: Types, Design & Performance Optimization

Release time:

Jun 27,2025

Source:

I. Introduction

Transformers are indispensable components within modern power systems. They serve as critical nodes, enabling the conversion of electrical energy between different voltage levels to meet diverse equipment and user requirements. Whether stepping down high voltage (HV) for residential/commercial use or stepping up low voltage (LV) for efficient long-distance transmission, transformers play a vital role. Their stable operation impacts not only power supply quality but also system safety and economic efficiency.

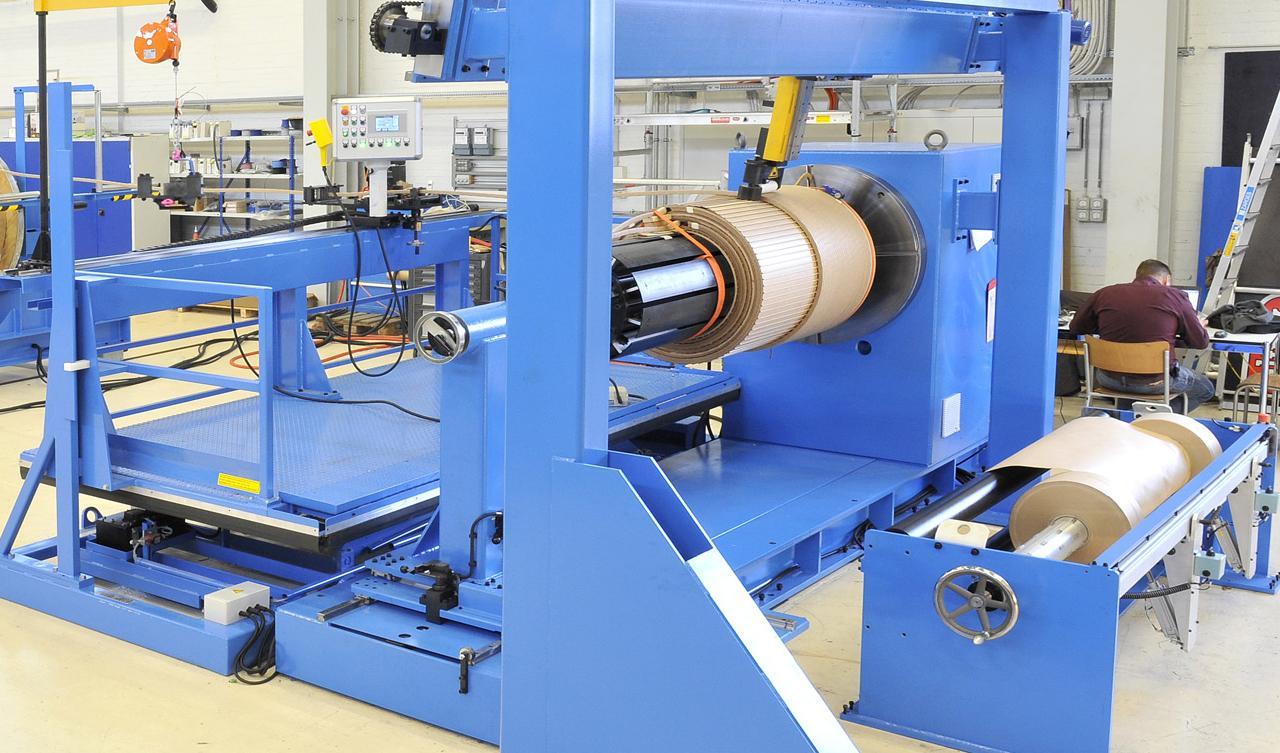

Transformer windings—the core components—directly handle current and voltage transformation. Their design and manufacturing quality dictate transformer performance and lifespan. Different structural types (layer, disk, continuous, interleaved windings) offer unique advantages suited to specific applications. Understanding these windings is essential for design, manufacturing, operation, and maintenance.

II. Basic Overview of Transformer Windings

1. Definition and Function

Transformer windings consist of conductive material (typically copper or aluminum wire) wound into coils. Their primary function is electromagnetic energy conversion and transfer. Alternating current in the primary winding generates a magnetic field, inducing voltage in the secondary winding to achieve step-up/step-down transformation. Windings also serve as connection points between the power source and load.

2. Basic Structure and Components

Key components include:

Conductor: High-conductivity copper/aluminum wire; cross-section selected based on capacity/current.

Insulation: Separates conductive parts to prevent electrical breakdown/short circuits; requires excellent electrical/thermal properties.

Support Structure: Stabilizes windings mechanically; made of insulating materials (pressboard, fiberglass).

Leads: Connect windings to external circuits via insulated bushings.

III. Types of Transformer Windings

1. Layer Winding (Stacked Conductive Layers)

Constructed by stacking parallel conductor layers separated by insulation.

Pros: Simple structure, easier manufacturing, better cooling (air gaps between layers).

Cons: Lower space utilization → reduced capacity per volume; suitable for LV/mid-capacity units.

2. Disk Winding

Formed from disk-shaped conductor groups stacked axially.

Pros: High space utilization → larger capacity; superior mechanical strength for HV/high-power applications.

Cons: Poorer thermal performance → requires enhanced cooling.

3. Continuous Winding

A single, uninterrupted helical winding without layer breaks.

Pros: Compact structure, excellent electromagnetic performance (reduced leakage flux/eddy losses).

Cons: Complex manufacturing (precision equipment needed); restricted cooling.

4. Interleaved Winding (Cross-Bonded)

Features intentional crossovers between adjacent layers to boost coupling.

Pros: Minimized leakage flux → higher efficiency.

Cons: Highly complex manufacturing; cooling challenges.

IV. Comparative Analysis of Winding Types

| Characteristic | Layer Winding | Disk Winding | Continuous Winding | Interleaved Winding |

|---|---|---|---|---|

| Structure | Simple, layered | Compact disks | Helical, no breaks | Complex crossover |

| Cooling | Good (air gaps) | Moderate* | Moderate | Moderate* |

| EM Performance | Moderate leakage | Low leakage | Very low leakage | Minimal leakage |

| Mechanical Strength | Moderate | High | Depends on design | Moderate |

| Typical Use | LV/mid-capacity | HV/high-power | High EM demands | Specialized HV |

*Requires additional cooling measures

V. Key Factors in Winding Design & Selection

Power Rating & Voltage: Determines conductor size and complexity.

Cooling & Temperature Rise: Impacts insulation lifespan; requires material/structural optimization.

EM Performance & Short-Circuit Impedance: Affects efficiency/stability under fault conditions.

Mechanical Strength & Seismic Resilience: Critical for durability under electromagnetic/mechanical stress.

Cost & Maintainability: Balances performance with production/maintenance efficiency.

VI. Manufacturing & Maintenance

1. Manufacturing Process Flow:

Material Prep → Conductor Treatment → Precision Winding → Insulation Application → Core Assembly → Rigorous Testing

2. Quality Control Focus Areas:

Material compliance

Winding tension/speed/temperature

Insulation integrity (no voids/gaps)

Dimensional accuracy

Electrical/mechanical validation

3. Operational Maintenance:

Regular Inspections: Visual checks for damage/discoloration; verify structural integrity.

Thermal Monitoring: Detect abnormal hotspots proactively.

Cleaning/Dust Prevention: Maintain cooling efficiency.

Preventive Maintenance: Tighten components; replace aged insulation.

Fault Response: Immediate shutdown → root cause analysis → repair/replacement.

VII. Future Trends

Material Innovation: High-conductivity composites, nanomaterials, superconductors for efficiency gains.

Smart Manufacturing: AI-driven design optimization; robotic winding automation.

Additive Manufacturing: 3D printing for complex geometries and waste reduction.

Grid Modernization: Sensor-integrated windings enabling real-time health monitoring in smart grids.

Renewable Integration: Windings engineered for HV/high-current stability in solar/wind applications.

Why Trust Our Expertise?

For over 15 years, we’ve engineered transformer that balance precision, durability, and efficiency. Our solutions are rigorously tested—ensuring your operations run smoothly, safely, and cost-effectively.

Explore our transformer solutions →https://www.aisite-ast.com/Solution.html

Need a custom design? → Contact our Team Now

📧 Email: [sale@aisite-ast.com]

📞 Phone/Whatsapp: [+86 15896663407]

keyword:

Previous page:

RELATED NEWS