Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Rectifier transformer: core equipment for AC/DC conversion in power systems

Release time:

May 09,2025

Source:

Rectifier transformer is a special transformer designed for AC/DC conversion, which is widely used in industry, rail transit, new energy and high-voltage power transmission. As an "intelligent bridge" connecting AC power grid and DC load, it not only realizes efficient energy transmission, but also undertakes key tasks such as voltage regulation, harmonic suppression and system protection. According to statistics from the International Energy Agency (IEA), about 65% of the world's industrial DC power systems rely on rectifier transformers to achieve power conversion. Thus, in the artilce, we will introduce rectifier transformers to you in detail from five aspects.

一. Working principle and structural characteristics of rectifier transformer

1. Core working principle

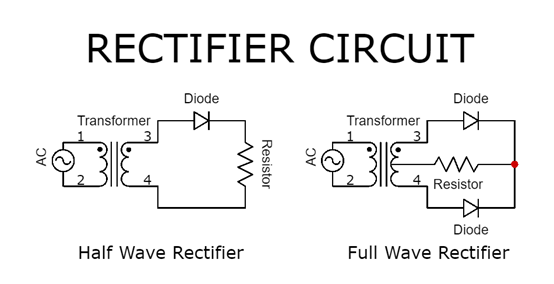

The rectifier transformer converts the input AC voltage into AC power of the required amplitude through the principle of electromagnetic induction, and then cooperates with the rectifier (such as thyristor, IGBT) to perform AC-DC conversion. Its core process is:

AC input → transformer voltage regulation → rectifier conversion → DC output

Key parameters:

Output DC voltage range: 48V (electroplating) to ±1100kV (UHV transmission)

Current capacity: up to 200kA (aluminum electrolysis industry)

2. Unique design structure

Compared with ordinary transformers, rectifier transformers need additional considerations in design:

Anti-harmonic winding: adopt multi-winding phase shift design (such as 12-pulse, 24-pulse) to reduce harmonic interference

Enhanced heat dissipation system: configure forced oil circulation (OFAF) or air cooling device to cope with high load heating

DC bias suppression: add air gap or magnetic shielding layer to prevent DC current from causing core saturation

二. Core functions and advantages of rectifier transformers

1. Efficient energy conversion

Conversion efficiency of more than 98% (in compliance with IEC 60076 standard)

Supports bidirectional energy flow (applicable to photovoltaic energy storage systems)

2. Accurate voltage adaptation

Match different load requirements through multi-tap adjustment or series reactor

Example: Metro traction system reduces 10kV AC to 750V DC

3. Grid protection and stability

Harmonic filtering: 12-pulse design can eliminate 5th and 7th harmonics, THD < 5%

Fault isolation: Quickly cut off the short-circuit current on the DC side to protect the AC grid

三. Industry application scenarios and technological breakthroughs

| Industry Application | Requirements | Technical Solutions |

| Electrolysis | High current (100-200kA), low voltage(<50V) | Multi-parallel windings + water cooling |

| HVDC Transmission | Ultra-high voltage (±800kV-±1100kV) | low loss Oil-immersed insulation + split converter transformer design |

| Urban Rail Transit | Dynamic load response | High-impedance windings + intelligent temperature control system |

四. Selection Guide: How to choose a suitable rectifier transformer?

1. Key selection parameters

Output capacity: calculated based on DC load power (kW) and current (kA)

Number of pulses: 6 pulses (basic), 12 pulses (low harmonics), 24 pulses (precision equipment)

Protection level: IP55 (outdoor dust and water proof), IP23 (indoor ventilation environment)

2. Maintenance and cost optimization suggestions

Life cycle cost (LCC): choose a fully sealed oil-immersed design to reduce maintenance frequency

Intelligent upgrade: install an online monitoring system (such as DGA oil chromatography analysis) to prevent failures

五. Future Trends: The Role of Rectifier Transformers in Smart Grids

With the development of new energy grid connection and digital grid, rectifier transformers are moving towards:

Greening: Using biodegradable insulating oil (such as FR3) to reduce carbon emissions

Intelligentization: Monitor temperature, vibration and insulation status in real time

Modularization: Prefabricated converter station design to shorten the construction period of high-voltage transmission projects

keyword:

Previous page:

Next page

Previous page:

Next page

RELATED NEWS