Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Working Principle and Application of Three-phase Dry-type Transformer

Release time:

May 13,2025

Source:

In modern power systems, transformers are vital equipment used to change the size of voltage and transmit voltage. Among these transformers, dry-type transformers are a common type, and their advantages include oil-free, pollution-free and non-flammable. Therefore, this article will review the working principle, structural characteristics and application fields of three-phase dry-type transformers in order to better understand their principles and usage characteristics.

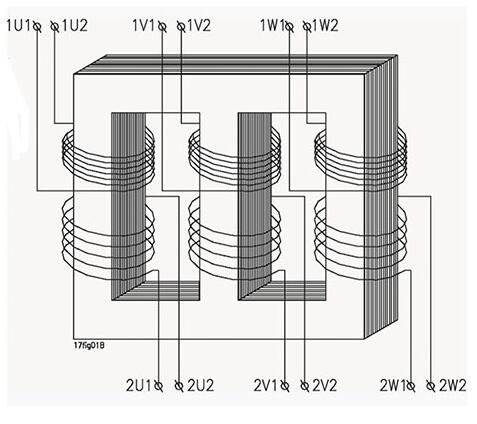

The three-phase dry-type transformer is a dry-type transformer that uses air as a cooling medium and no oil for insulation. Its working principle is basically the same as other types of transformers, that is, it changes voltage through the law of electromagnetic induction. The main feature of the dry-type transformer is that its magnetic circuit part has no oil, but is insulated with special insulating materials. This eliminates some of the shortcomings of oil-immersed transformers, such as oil leakage and easy fire.

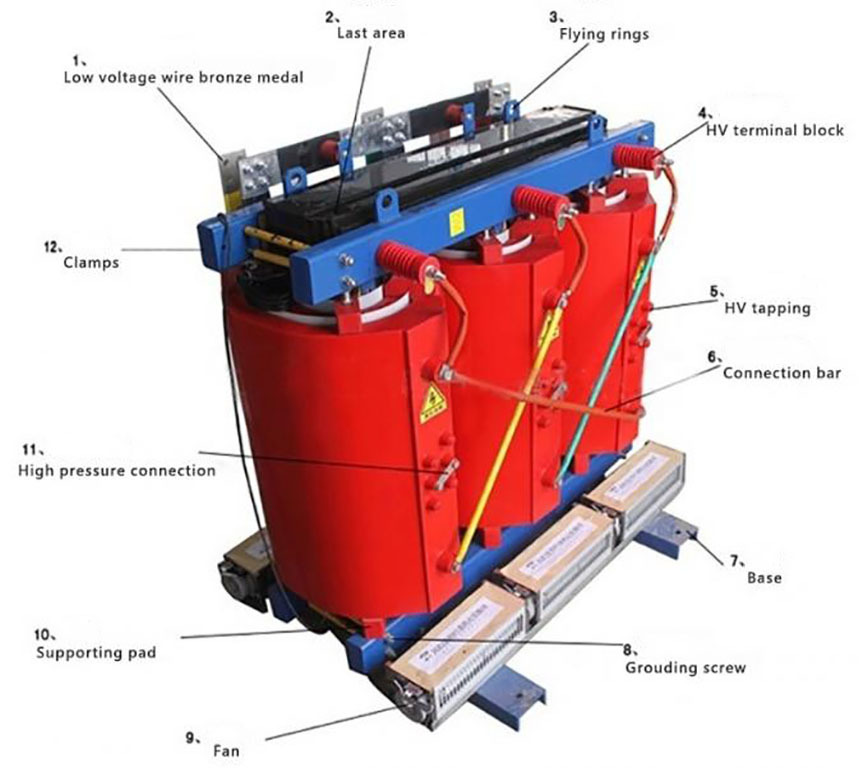

The main structure of this transformer includes a magnetic circuit part and a winding part. The magnetic circuit part is composed of magnetic materials such as silicon steel sheets, which are used to conduct magnetism and generate magnetic flux. The winding part is composed of coils, and voltage conversion is achieved through mutual induction. On the winding, multiple layers of insulating paper or insulating sheets are usually used for insulation and isolation. This special structure makes the dry-type transformer have good insulation performance and high voltage resistance.

Details of important components

1. Core material:

The core materials used in transformers are mainly iron sheets, low silicon sheets, and high silicon sheets. Adding silicon to steel sheets can reduce the conductivity of steel sheets and increase resistivity. It can reduce eddy current and reduce its loss. We usually call the steel sheets with silicon added as silicon steel sheets. The quality of the transformer is closely related to the quality of the silicon steel sheets used. The quality of silicon steel sheets is usually expressed by the magnetic flux density B. The B value of black iron sheets is generally 6000-8000, low silicon sheets are 9000-11000, and high silicon sheets are 12000-16000.

2. The materials commonly used for winding transformers are

Enameled wire, sand-wrapped wire, silk-wrapped wire, and the most commonly used enameled wire. The requirements for the wire are good conductivity, sufficient heat resistance of the insulating paint layer, and certain corrosion resistance. In general, it is best to use high-strength polyester enameled wire of model Q2.

3. Insulation materials

In the winding transformer, the isolation between the coil frame layers and the isolation between the windings must use insulating materials. The general transformer frame material can be made of phenolic paperboard, the layers can be isolated with polyester film or telephone paper, and the windings can be isolated with yellow wax cloth.

4. Impregnation materials:

After the transformer is wound, it has to go through the last process, which is impregnation with insulating varnish, which can enhance the mechanical strength of the transformer, improve the insulation performance, and extend the service life. Under normal circumstances, cresol varnish can be used as the impregnation material.

Three-phase dry-type transformers have a wide range of uses in practical applications. It is often used in distribution substations, factories, mines and other occasions where voltage transformation is required. Due to its oil-free and pollution-free characteristics, the three-phase dry-type transformer can operate stably for a long time under harsh environmental conditions. At the same time, it has low energy consumption, high efficiency, and good anti-interference and overload capabilities, and can adapt to complex and changing power environments.

In recent years, the technology of three-phase dry-type transformers has continued to develop. Its product structure design has become mature, and a series of advanced technologies have been adopted to improve performance. For example, segmented windings can effectively reduce the generation of electromagnetic waves and noise; fully enclosed structures improve insulation performance and operational safety; at the same time, the use of automated control and testing technology reduces human interference during the manufacturing process.

However, in practical applications, three-phase dry-type transformers still face some problems that need to be solved. Due to the limitations of heat dissipation methods, high temperature rise may occur during long-term operation, which may affect its service life. In addition, due to its complex structure and relatively high manufacturing cost, it is limited to its promotion and application in some occasions.

In summary, three-phase dry-type transformers are widely used in modern power systems as an important transformer equipment. Although its working principle is similar to that of other types of transformers, its oil-free and pollution-free dry design is one of its characteristics. In practical applications, it has good insulation performance, high voltage resistance and operational stability. However, problems such as heat dissipation and manufacturing costs still need to be solved. It can be foreseen that with the further development and improvement of technology, three-phase dry-type transformers will play a more important role in future power systems.

keyword:

RELATED NEWS