Welcome to the official website of Luoyang AISITE Transformer Co., LTD

How to maintain oil-immersed transformers

Release time:

May 30,2025

Source:

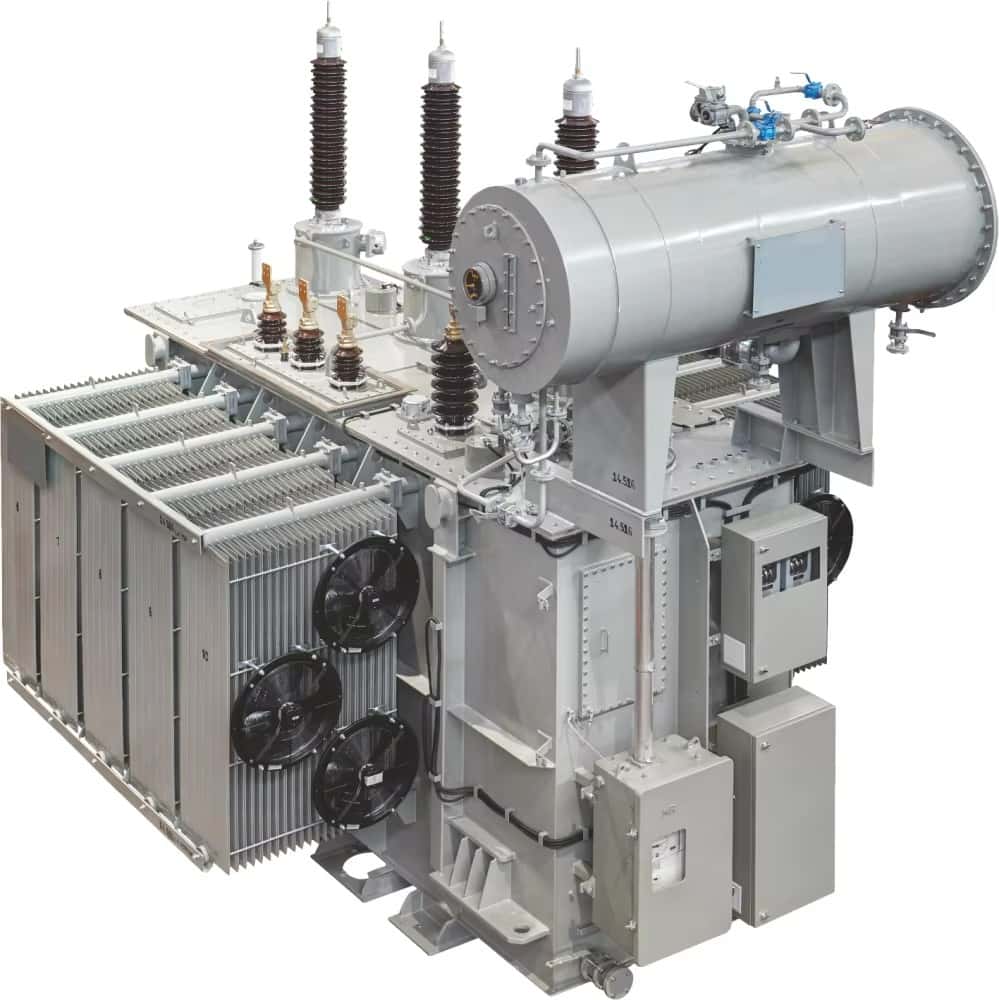

As one of the important equipment in the power system, oil-immersed transformers are widely used in various industrial and civil power facilities. In order to ensure its long-term stable operation, regular maintenance is particularly important. The following will focus on the maintenance points of oil-immersed transformers.

1. Regularly check the oil level and oil quality

The oil tank of the oil-immersed transformer is filled with insulating oil. The quality of the oil directly affects the insulation performance and heat dissipation capacity of the transformer. Therefore, it is very important to regularly check the oil level and oil quality of the transformer. Too low oil level will cause the transformer to overheat, and poor oil quality may reduce the insulation strength of the transformer. Check the oil level regularly to ensure that the oil level is appropriate, and use oil sample testing to determine whether the oil quality meets the requirements. When the oil quality is abnormal, the insulating oil should be replaced in time.

2. Clean the surface of the transformer

During operation, the transformer will accumulate dust, oil stains and other debris, which will not only affect the heat dissipation effect of the transformer, but also may cause failures. Regularly clean the outside of the transformer and keep its surface clean, which will help extend the service life of the equipment. At the same time, check whether there is leakage on the surface of the oil tank to avoid oil leakage from polluting the environment.

3. Check the grounding system of the transformer

The grounding system of the transformer is crucial to the safety of the equipment. The good operation of the grounding system can effectively prevent the harm of the equipment when an electrical fault occurs. During the maintenance process, check whether the grounding resistance meets the standard to ensure that the connection of the grounding system is firm and reliable. If poor grounding is found, the grounding facilities should be repaired or replaced in time.

4. Monitor temperature and load conditions

The temperature change of the oil-immersed transformer is directly related to its normal operation. During the maintenance process, check the temperature of the transformer regularly, especially when the load changes greatly. Excessive temperature may cause aging of the transformer insulation, and in severe cases may cause failures. Through the temperature monitoring instrument, the operating temperature of the transformer is monitored in real time to avoid overload operation and ensure that it is always within the safe working range.

5. Regular oil sample testing and degassing

In order to ensure the oil quality of the oil-immersed transformer, it is necessary to conduct oil sample testing regularly. Through oil sample testing, you can understand the moisture, acid value, gas content, etc. in the oil, and discover potential insulation problems in advance. At the same time, if the gas content in the oil is found to be high, degassing should be carried out to prevent gas accumulation from affecting the insulation performance of the transformer.

6. Regular maintenance inspection and record keeping

During the maintenance process, the operator should regularly conduct various inspections and keep records. The inspection content includes the operating status, oil level, oil quality, temperature, load and grounding system of the transformer. After each inspection, record the relevant data and take corresponding treatment measures according to the test results.

Summary

The maintenance of oil-immersed transformers is an important part of ensuring equipment safety and extending service life. By regularly checking the oil level, oil quality, temperature and grounding system, potential faults can be effectively prevented and the transformer can be ensured to operate stably for a long time. Therefore, power system maintenance personnel should attach great importance to the daily maintenance of transformers to ensure the safety and reliability of equipment.

If you encounter any problems in the use and selection of transformers, please feel free to contact us. As a transformer manufacturer with 15 years of production experience, we have rich production and sales experience, as well as a professional technical team, including 13 senior engineers, and we can provide you with professional and timely solutions.

Connect via WhatsApp: +86-15896663407 | Email: sale@aisite-ast.com

keyword:

RELATED NEWS