Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Power Transformer Iron Loss and Copper Loss

Release time:

Feb 06,2025

Source:

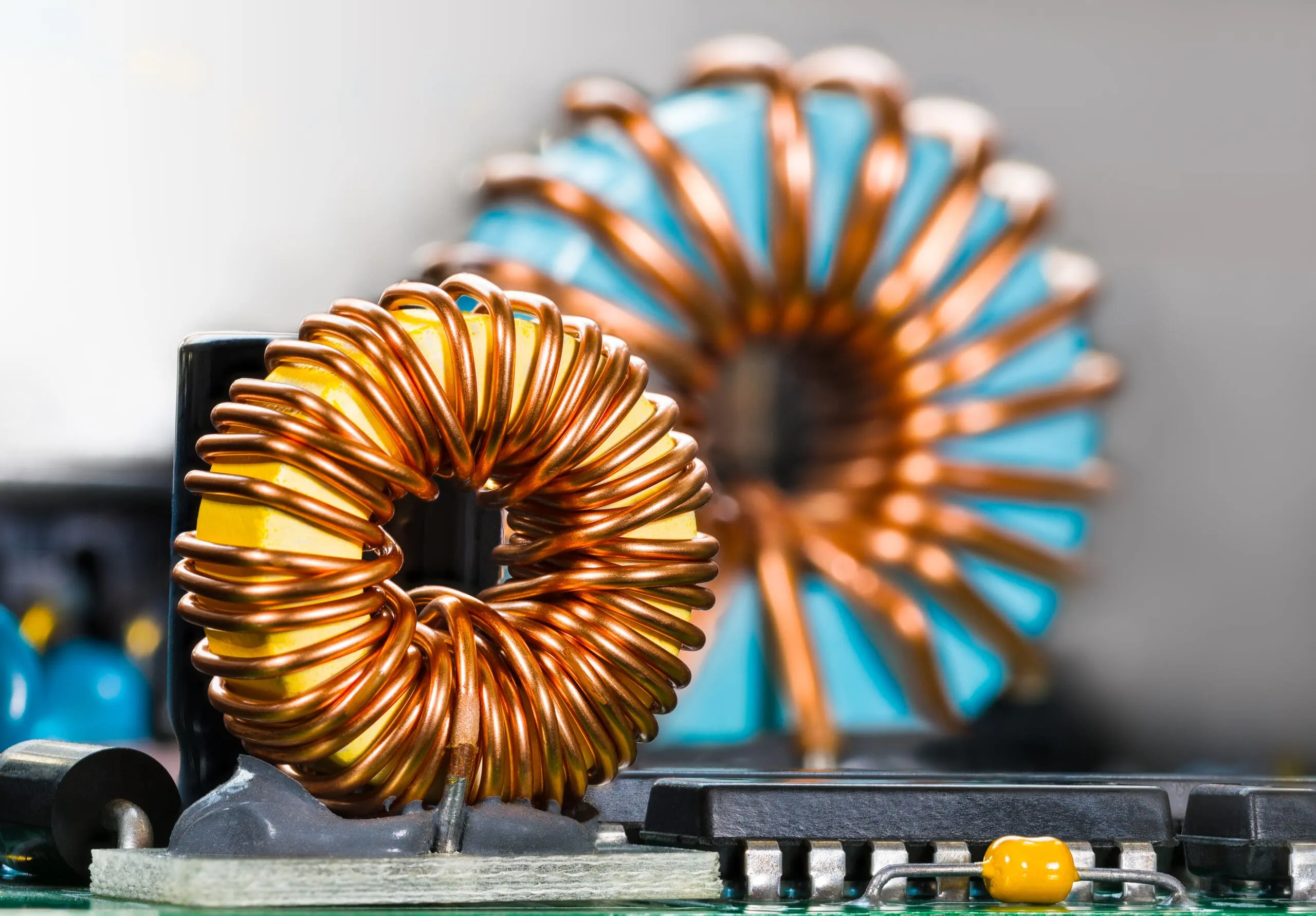

Any kind of electrical equipment will suffer losses during long-term operation, and power transformers are no exception. In the loss of power transformers, it is mainly divided into copper loss and iron loss.

What is Iron Loss?

Iron loss, also known as core loss, happens in the transformer's core due to the continuous magnetization and demagnetization of the material. It consists of two main components:

1,Hysteresis Loss: This occurs because the core material resists changes in magnetization, causing energy to be dissipated as heat.

2,Eddy Current Loss: Changing magnetic fields induce unwanted circulating currents within the core, leading to energy loss in the form of heat.

What is Copper Loss?

Copper loss refers to the energy lost as heat in the transformer's windings due to electrical resistance. It is directly proportional to the square of the current flowing through the winding and can be calculated as:

Copper Loss (Pcu) = I²R

Where:

I = Current through the windings

R = Resistance of the windings

Since copper loss depends on the load, it fluctuates during transformer operation.

Effects of Iron Loss and Copper Loss

Both iron and copper losses impact transformer performance in several ways:,

1,Higher Operating Costs: Increased energy consumption leads to higher electricity bills.

2,Excessive Heat Generation: Too much heat can damage insulation and shorten transformer lifespan.

3,Lower Efficiency: Transformers with high losses waste more energy, reducing overall effectiveness.

How to Reduce Iron Loss and Copper Loss

To improve efficiency and reduce losses, manufacturers implement various design and material enhancements:

Reducing Iron Loss

1,Use high-quality silicon steel with low hysteresis.

2,Laminate the core to reduce eddy currents.

3,Optimize core design to minimize unnecessary magnetic flux leakage.

Reducing Copper Loss

1,Use low-resistance copper windings to cut down on I²R losses.

2,Increase conductor size to reduce electrical resistance.

3,Implement better cooling systems to manage temperature-dependent resistance.

Conclusion

Iron and copper losses are key factors affecting transformer efficiency. By utilizing superior materials, refining design, and improving cooling systems, these losses can be significantly reduced, leading to cost-effective and high-performance transformers. Investing in energy-efficient transformers not only saves money but also contributes to a more sustainable future.

For top-quality, low-loss transformers, AISITE Transformer offers reliable and efficient power solutions. Contact us today to learn more about our advanced transformer technology!

keyword:

Previous page:

RELATED NEWS