Welcome to the official website of Luoyang AISITE Transformer Co., LTD

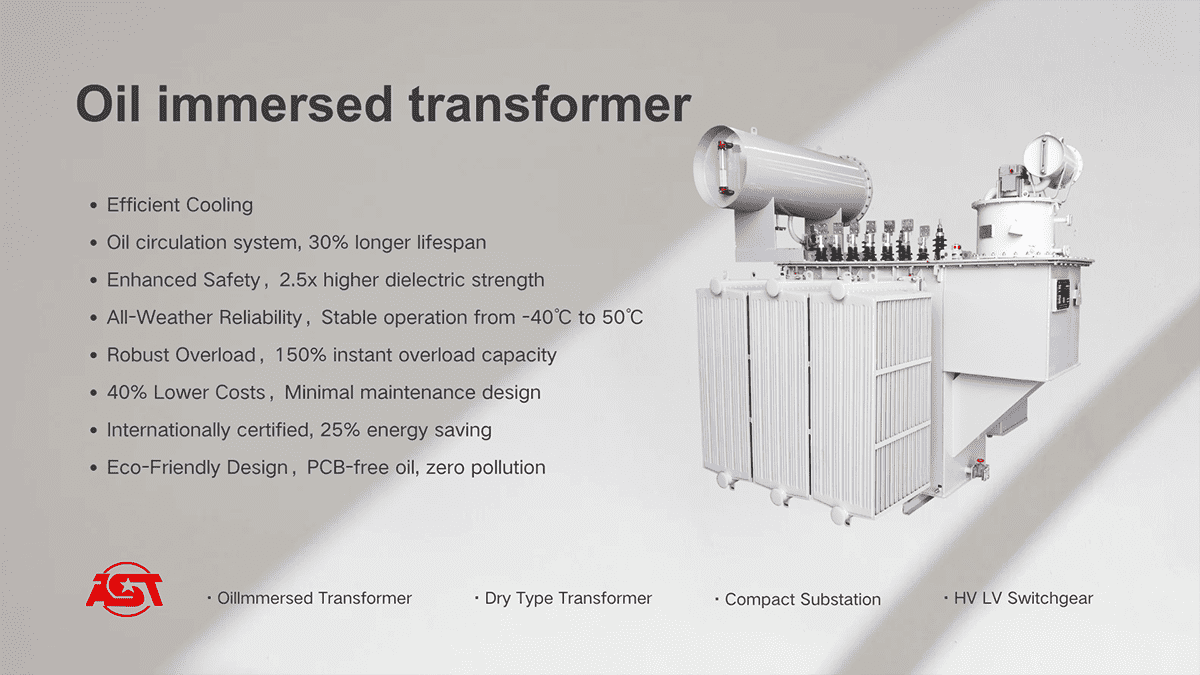

110KV Oil Immersed Transformer/ 110KV Power Transformer

110kV oil-immersed power transformer has the characteristics of large capacity, high voltage, oil-immersed cooling and good insulation performance, and is widely used in power plants, substations, industrial enterprises and urban power grids. As a professional transformer manufacturer with 15-year experience, AISITE can provide you with reliable products and service.

keyword:

110KV Oil Immersed Transformer/ 110KV Power Transformer

DESCRIPTION

Product Description

110kV oil-immersed power transformer is one of the indispensable and important equipment in the power system. It has the characteristics of large capacity, high voltage, oil-immersed cooling and good insulation performance, and is widely used in power plants, substations, industrial enterprises and urban power grids. When selecting and using 110kV oil-immersed transformers, it is necessary to fully consider its performance characteristics, application scope and maintenance factors to ensure the safe, stable and economical operation of the power system.

Power Transformer Features

Rated power up to 100 MVA

Rated insulation level up to 170 kV

Rated frequency 50 or 60 Hz

Mineral oil insulating liquid

Low flammability dielectric liquids

Hermetically sealed or breathing with conservator

Conventional or reduced losses

High capacity of cooling options such as ONAN, ONAF, OFAF or OFWF (also with K class insulating oil)

Off-Circuit Tap Changer (OCTC) or On-Load Tap Changer (OLTC)

Wide range of accessories

Rectifier feeder (Rectifier Transformers range)

High reliability in harsh environments

Customized design and bespoke manufacturing

Long service life with minimal maintenance

Available with MV & LV Switchboard

Ease of Installation

Large capacity: 110kV oil-immersed power transformers usually have a large capacity and can meet the needs of large-scale power transmission and distribution.

High voltage: Its rated voltage is 110kV, which is suitable for access and transmission of high-voltage power grids.

Oil-immersed cooling: Transformer oil is used as the cooling medium, and the heat generated inside the transformer is taken away by the circulation of oil to ensure that the transformer can operate stably under rated load.

Good insulation performance: The heat generated inside the transformer is removed by the circulating flow of oil, ensuring that the transformer can operate stably under rated load.

Compact structure: Reasonable design, compact structure, small footprint, easy installation and transportation.

Power Transformer Configurations

1 | Oil filter valve | 17 | Oil drain valve |

2 | Conservator | 18 | Jacking boss |

3 | Buchholz relay | 19 | Stopper |

4 | Oil filter valve | 20 | Foundation bolt |

5 | Pressure-relief vent | 21 | Grounding terminal |

6 | High-voltage bushing | 22 | Skid base |

7 | Low-voltage bushing | 23 | Coil |

8 | Suspension lug | 24 | Coil pressure plate |

9 | B C T Terminal | 25 | Core |

10 | Tank | 26 | Terminal box for protective devices |

11 | De-energized tap changer | 27 | Rating plate |

12 | Tap changer handle | 28 | Dial thermometer |

13 | Fastener for core and coil | 29 | Radiator |

14 | Lifting hook for core and coil | 30 | Manhole |

15 | End frame | 31 | Lifting lug |

16 | Coil pressure bolt | 32 | Dial type oil level gauge |

Production Process

1.Core processing

The core is the core of the transformer. Its function is to conduct magnetism and transmit electrical energy. During the production process, the core will be assembled according to the requirements of different types of transformers. The core sheets are precisely cut and stacked to ensure the stability of its shape and structure. The assembled core will be sent to the next winding process.

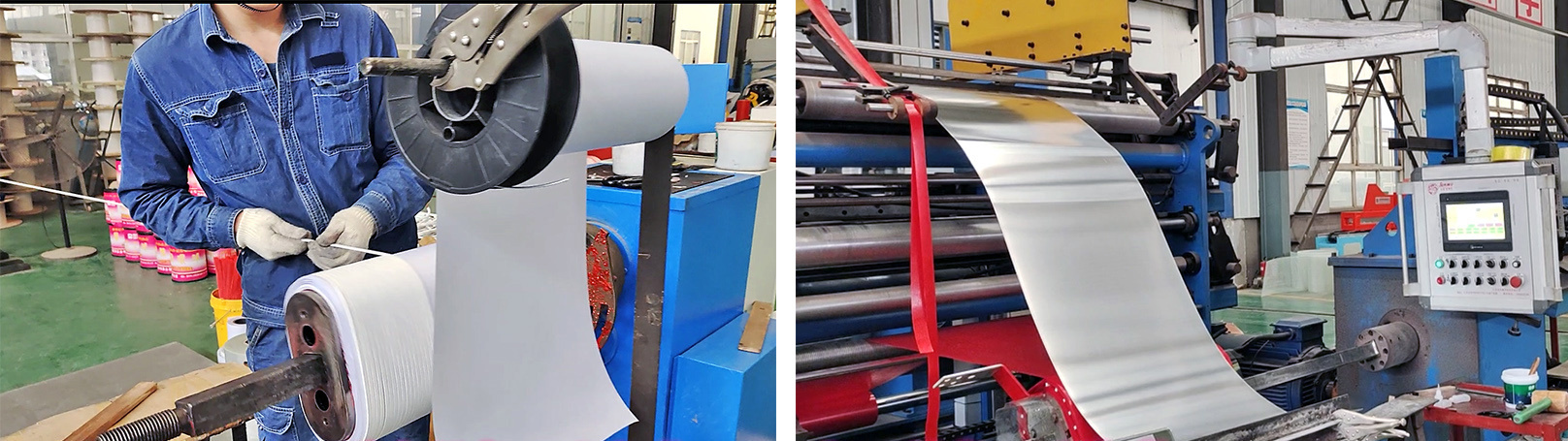

2.Winding manufacturing and installation

Winding is an important part of oil-immersed power transformers, usually divided into high-voltage winding and low-voltage winding. During the manufacturing process, the winding wire is wound around the core at a specific position by mechanical equipment to ensure that it can efficiently transmit current. At this stage, the insulation of the winding is crucial, so each step needs to be strictly controlled.

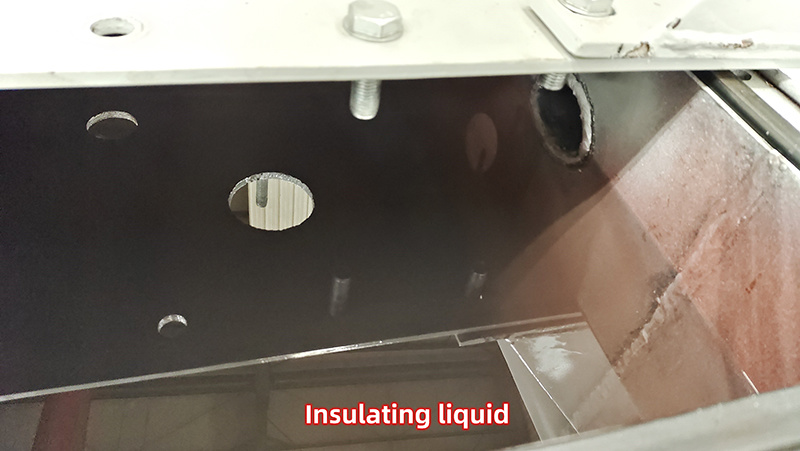

3.Insulating liquids

The layer insulation is adapted to the alternating voltage strain that occurs in daily operation. Large-scale oil channels are provided to ensure sufficient cooling of the windings and to avoid hot spots. All leads are short-circuit-proof and surge-proof, contributing to the high reliability of thetransformer – and to an above-average service life.

4.Tank & Cooling

Whether during transport or operation, the tank must remain sealed tight under mechanical stress and regardless of wind or weather. Corrosion protection is especially important. The surface is sandblasted and then multicoated. Upon request, hot-dip galvanization can provide even better protection.

5.Final assembly

The transformer’s core-and-coil assembly consists of the core, windings, and connecting cables. High-quality drying and quick filling with insulation oil play a key role in extending the transformer’s service life.Aisite employs the latest techniques. For example, in vacuum low-frequency plants (LFH – low-frequency heating), the process of drying the solid insulation is combined with vacuum drying of the windings through low-frequency heating. The active part is heated by applying low-frequency current (< 1 Hz) to the high-voltage windings with the low-voltage windings short-circuited. While still in the plant, transformers are filled with preheated insulation liquid which is absorbed by the insulation material, thus preventing the intake of oxygen.

Regular Maintenance and Care of Power Transformer

In order to ensure the long-term stable operation of 110kV oil-immersed transformers, regular maintenance and care are required.

1.Checking the transformer's oil level, oil temperature, oil quality, insulation performance and other parameters;

2.Timely cleaning the dirt and dust on the transformer surface;

3.Regularly replacing aging and damaged parts;

4.In addition, attention should be paid to the transformer's operating environment to avoid adverse factors such as humidity, high temperature and corrosive gases.

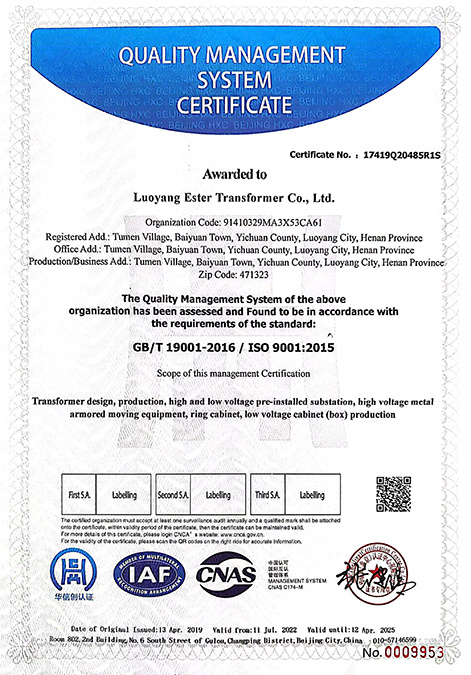

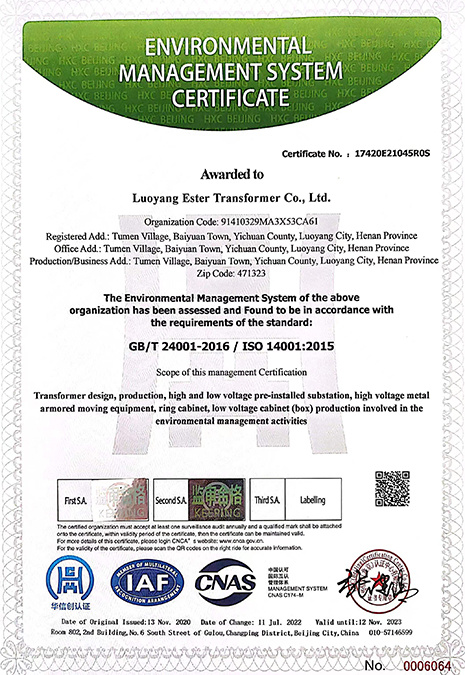

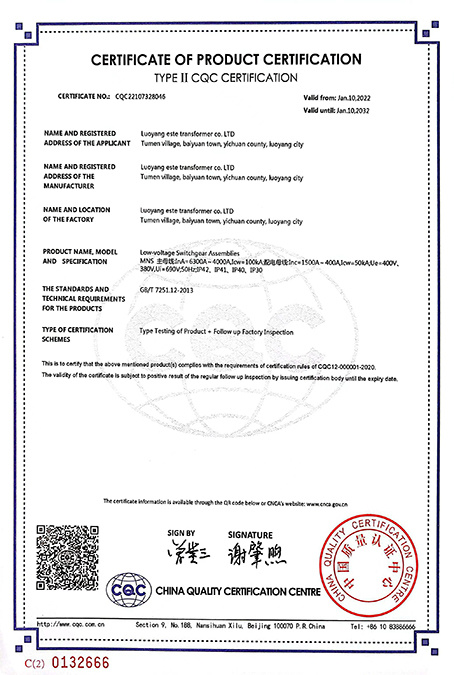

Certificate

Our Team

Sale Cases

Previous page

Next page

Previous page

Next page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China