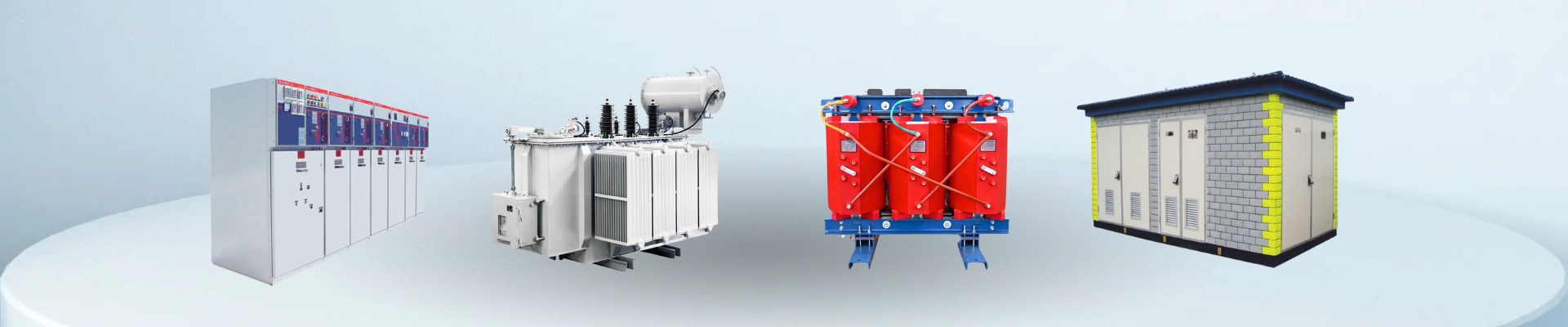

Welcome to the official website of Luoyang AISITE Transformer Co., LTD

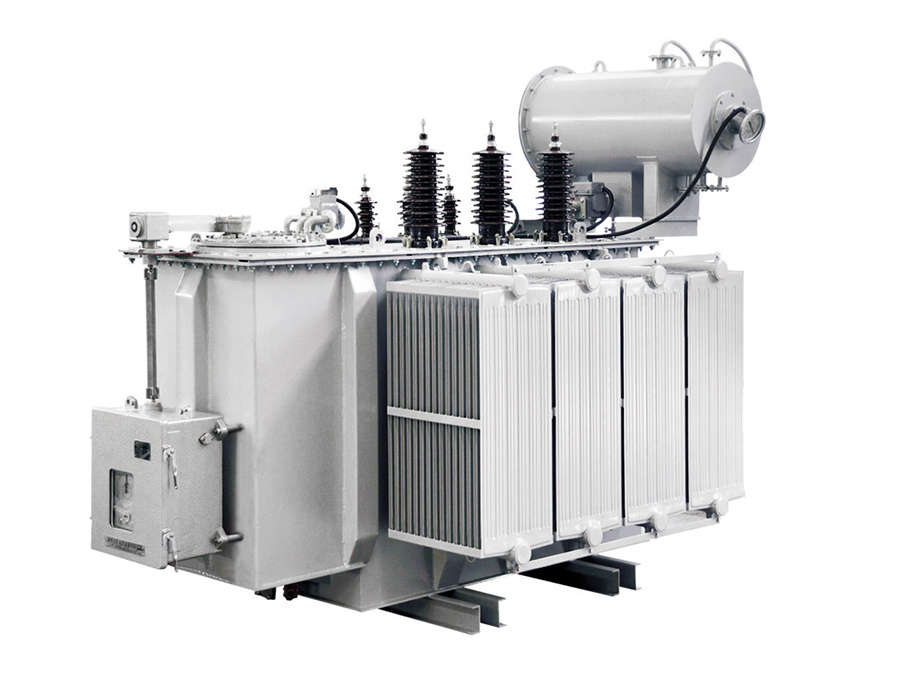

35KV Oil Immersed Transformer

Type: Oil Immersed Transformer/ Oil Filled Transformer Phase: Three-phase Voltage Range: 35kV-38.5kV Vector Group: Yyn0; Dyn11

keyword:

35KV Oil Immersed Transformer

DESCRIPTION

Product Introduction

35kV oil-immersed transformer (also known as oil filled transformer) is widely used in medium to high-voltage electrical systems for stepping up or stepping down voltage levels. It is typically installed in power distribution networks, substations, or industrial facilities. The term "35kV" refers to its rated high-voltage capacity, making it suitable for handling substantial electrical loads and ensuring efficient energy transmission over long distances.

Features

1.The 35kV series transformers have the advantages of low loss, low noise, strong lightning protection and anti-sudden short circuit capability, and beautiful appearance.

2.The transformer has four remote functions of "remote signaling, remote measurement, remote adjustment, and remote control", which can be remotely controlled by a computer to realize unmanned substation operation.

Structural features:

Oil-immersed/filled design: The winding and core of the transformer are immersed in insulating oil. This design can effectively improve the heat dissipation performance of the transformer and ensure that the transformer can operate stably in a high temperature environment.

Winding structure: Multi-layer cylindrical or continuous windings are usually used to increase the mechanical strength and electrical performance of the windings.

Core structure: The core is the magnetic circuit part of the transformer, which is generally made of high-quality cold-rolled silicon steel sheets stacked to reduce magnetic flux loss and no-load current.

Technical Specification

Model | Rated power(kVA) | Rated primary voltage (kV) | Tapping(%) | Rated secondary voltage(no-load)(kV) | Vector group | No-load losses(W) | No-load current(%) | Rated impedance(%) |

| S13-M-30 | 30 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 80 | 2.3 | 4 |

| S13-M-100 | 100 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 150 | 1.8 | 4 |

| S13-M-200 | 200 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 240 | 1.5 | 4 |

| S13-M-400 | 400 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 410 | 1.3 | 4 |

| S13-M-500 | 500 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 480 | 1.2 | 4 |

| S13-M-800 | 800 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 700 | 1.0 | 4.5 |

| S13-M-1000 | 1000 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 830 | 1.0 | 4.5 |

| S13-M-1250 | 1250 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 970 | 0.9 | 4.5 |

| S13-M-1600 | 1600 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 1170 | 0.8 | 4.5 |

| S13-M-2000 | 2000 | 6/6.3/10/10.5 | ±2*2.5 ±5 | 0.4 | Yyn0 Dyn11 | 1510 | 0.8 | Customized |

| S13-M-2500 | 2500 | ±2*2.5 ±5 | 0.4 | 0.4 | Yyn0 Dyn11 | 1780 | 0.7 | Customized |

| S13-M-3150 | 3150 | ±2*2.5 ±5 | 0.4 | 0.4 | Yyn0 Dyn11 | 2100 | 0.7 | Customized |

Configurations

1 | Oil filter valve | 17 | Oil drain valve |

2 | Conservator | 18 | Jacking boss |

3 | Buchholz relay | 19 | Stopper |

4 | Oil filter valve | 20 | Foundation bolt |

5 | Pressure-relief vent | 21 | Grounding terminal |

6 | High-voltage bushing | 22 | Skid base |

7 | Low-voltage bushing | 23 | Coil |

8 | Suspension lug | 24 | Coil pressure plate |

9 | B C T Terminal | 25 | Core |

10 | Tank | 26 | Terminal box for protective devices |

11 | De-energized tap changer | 27 | Rating plate |

12 | Tap changer handle | 28 | Dial thermometer |

13 | Fastener for core and coil | 29 | Radiator |

14 | Lifting hook for core and coil | 30 | Manhole |

15 | End frame | 31 | Lifting lug |

16 | Coil pressure bolt | 32 | Dial type oil level gauge |

Production Process

FAQ

Q: How safe are oil-immersed transformers, particularly regarding fire risk?

A: Modern designs ensure safety. They use fire-resistant insulating oils (e.g., mineral oil meeting IEC 60296 or biodegradable ester fluids) within robust, sealed tanks. Pressure relief devices activate safely during internal faults, and designs comply with strict international safety standards (IEC).

Q: Is oil leakage a concern, and what maintenance is required?

A: Our transformers feature fully sealed construction (e.g., corrugated tanks or welded conservator tanks), minimizing leakage risk. High-quality insulating oil maintains stable chemical properties under normal operation. Maintenance primarily involves periodic oil sampling/testing and condition monitoring, reducing long-term upkeep.

Q: How are oil-immersed transformers protected during shipping?

A: We provide export-grade packaging: robust wooden crates, internal bracing/shock absorption, oil level monitoring, pressure gauge protection, and desiccants. Detailed transport and handling instructions ensure secure delivery.

Q: Are special foundations or space requirements needed for installation?

A: A level, robust foundation is essential to support the weight and minimize vibration. We supply precise dimensional drawings, foundation specifications, required clearances (safety zones), and ventilation guidelines for proper site preparation and installation.

Certificate

Our team

Sale Case

Previous page

Previous page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China