Welcome to the official website of Luoyang AISITE Transformer Co., LTD

12 pulse heat sink high overload medium frequency furnace special transformer

This transformer is engineered for medium-frequency induction melting furnaces. It incorporates 12-pulse rectification technology, an optimized cooling system, and defined overload capacity to support efficient metal smelting operations.

keyword:

12 pulse heat sink high overload medium frequency furnace special transformer

Category:

DESCRIPTION

Product Introduction

Engineered exclusively for modern medium-frequency induction melting furnaces, this transformer integrates 12-pulse rectification technology, advanced cooling systems, and high overload capacity. It solves three critical challenges in metal smelting—high energy consumption, harmonic pollution, and load surges—delivering efficient, stable, and eco-friendly melting operations.

Features

12-Pulse Rectification

Harmonic Suppression: Dual 30° phase-shifted outputs enable 12-pulse rectification, eliminating 5th/7th harmonics. Complies with IEEE 519/GB-T 14549 standards to avoid grid penalties.

Power Quality Boost: Reduces line losses and filter costs. Power factor >0.95.

Intensive Cooling System

ONAF Forced Cooling: High-flow oil pumps + turbo fans + expanded radiators limit temperature rise to ≤65K (vs. 75K per Chinese national standard).

High-Temp Insulation: Class H (180°C) materials withstand 150% short-term overload without derating.

Industrial-Grade Overload Capacity

Dynamic Load Handling: Supports 120% load for 30 mins and 150% for 10 mins (upgradeable). Handles cold-charge startup surges effortlessly.

Shock-Resistant Design: Reinforced windings endure furnace vibration.

Optimized for MF Furnaces

High Impedance (6-8%): Limits short-circuit current to protect power systems.

Low-Loss Core Steel: 15% lower no-load loss vs. national standards. Saves >$10k/year (for 2000kVA units).

Technical Specification

| Capacity | 1000~6000kVA(Customizable) |

| Primary Voltage | 6kV/10kV/35kV |

| Secondary Voltage | 400~1200V(Rectifier-matched) |

| Pulse Configuration | 12-pulse (/Y dual windings) |

| Cooling | ONAF(Oil-Air Forced Cooling) |

| Overload Capacity | 120% continuous (30 min), 150%(10 min) |

| Insulation Class | Class H (180℃) |

| Protection Rating | IP54 (Dust/water resistant) |

Application

Metal Smelting: Ferrous/non-ferrous metals (steel, copper, aluminum, zinc)

Foundry Lines: Paired with induction furnaces, holding furnaces, pouring systems

Scrap Metal Recycling: Melt systems for metal recovery

Superalloys: Specialty steels, precision alloy production

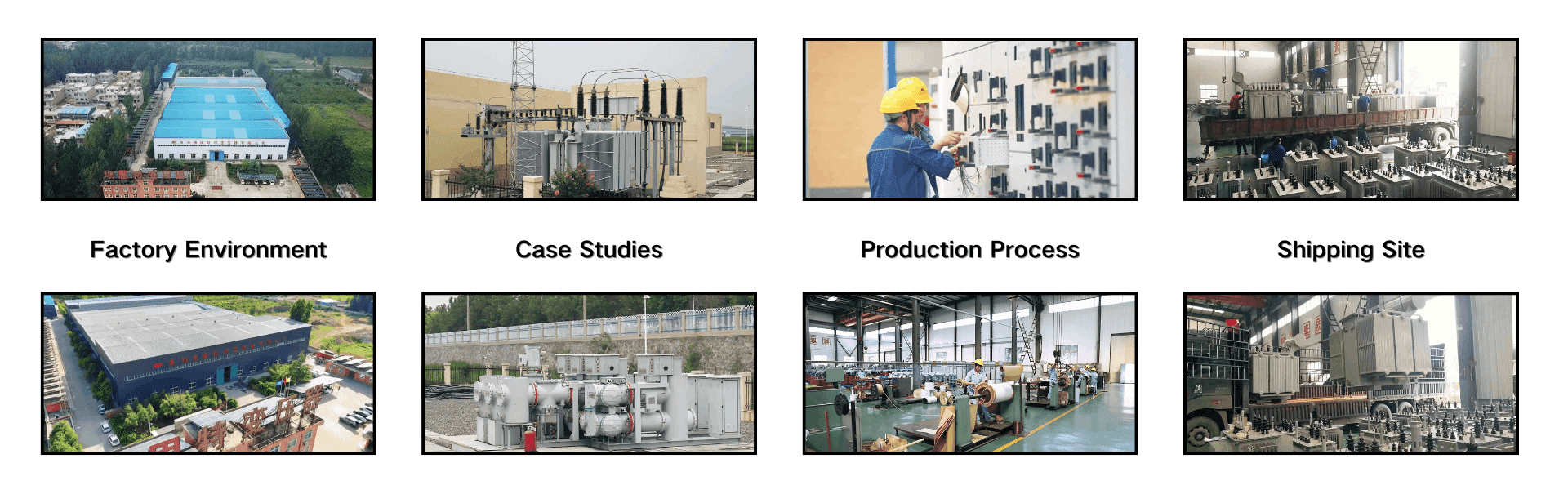

Our Factory

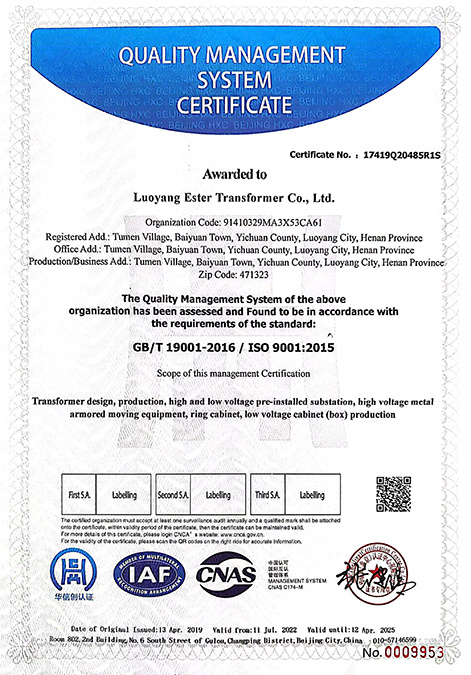

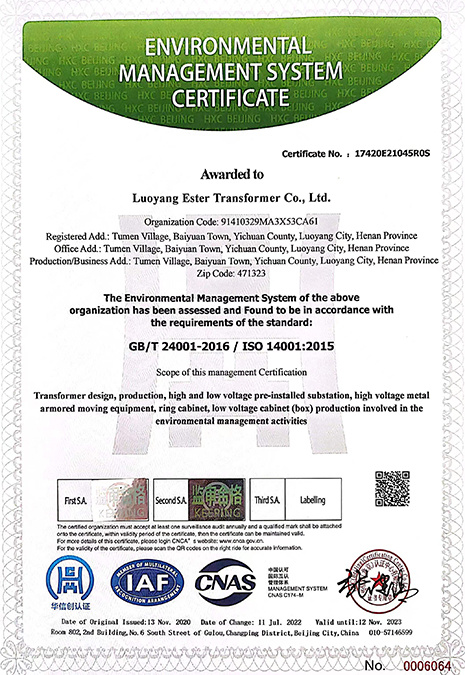

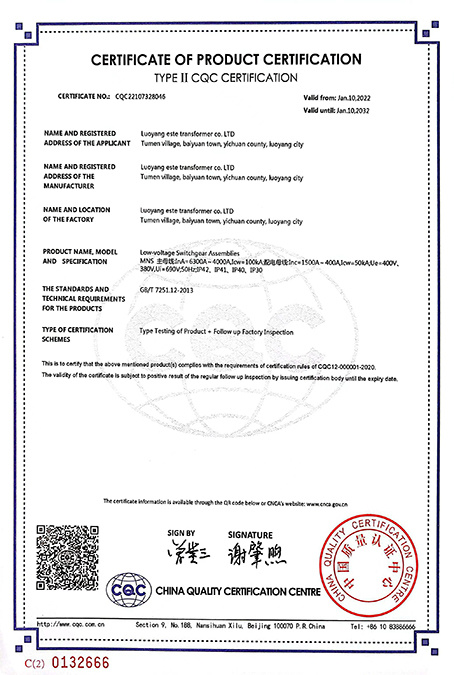

Certificate

Our Team

Sale Cases

Next page

Next page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China