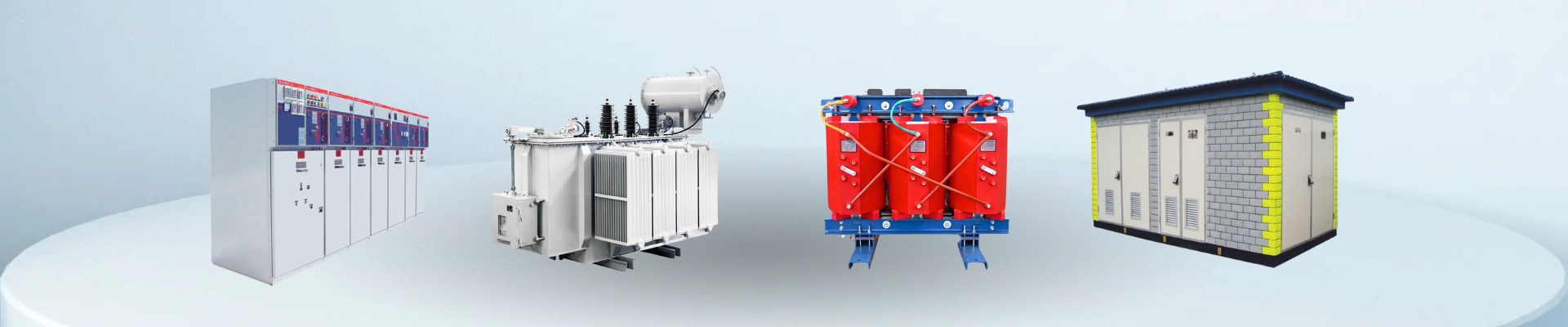

Welcome to the official website of Luoyang AISITE Transformer Co., LTD

12 pulse high overload medium frequency furnace dedicated transformer

12-pulse is used as the rectifier power supply of one-to-two medium frequency furnaces. It is a static variable frequency medium frequency power supply. It uses thyristor components to convert industrial frequency three-phase AC power into medium frequency single-phase AC power. It is mainly used in induction heating, induction melting and other occasions that require medium frequency furnace power supply.

keyword:

12 pulse high overload medium frequency furnace dedicated transformer

Category:

DESCRIPTION

Product Introduction

The high-end industrial frequency rectifier transformer designed for modern medium frequency induction melting furnaces integrates 12-pulse rectification technology and enhanced overload capacity to solve the problems of grid harmonic pollution and cold start impact in high-power melting. Through the dual secondary phase-shifted winding output, it provides stable and pure industrial frequency power conversion for the medium frequency power supply, which is suitable for high-demand industrial scenarios such as steel, copper, and precision casting.

Features

1. The control board uses advanced integrated circuits as the core of the control system, with strong control capabilities and high integration. The entire control circuit is installed on a printed circuit board of about 280*220mm. The connection with the main circuit is simple, but it has powerful control functions.

2. The 12-pulse medium frequency furnace uses three-phase power synchronous direct input, eliminating the large synchronous transformer, etc., which further simplifies the circuit of the whole machine, reduces the volume of the equipment, and is easy to install and debug and maintain. If the control system fails, just replace the spare board, saving time and effort, and not affecting production.

3. The 12-pulse medium frequency furnace has a complete multi-channel protection system such as overcurrent, overvoltage, current limiting, and voltage limiting. Once the circuit fails, the protection system can start in a short time and reliably protect precious components such as thyristors and medium frequency capacitors to avoid damage and unnecessary losses.

4. The 12-pulse medium frequency furnace control system adopts the functions of zero-voltage soft start and slow start, and adopts an advanced dual closed-loop adjustment system. In actual use, it can start 100% reliably and start without impact. In actual operation, the equipment can work stably and reliably even when the load changes greatly.

5. The 12-pulse medium frequency furnace control system has few adjustment points. After the control panel is installed, the user only needs to adjust the overcurrent, overvoltage, current limit and voltage limit.

6. The power supply equipment of the 12-pulse medium frequency furnace has strong adaptability to various loads and can be widely used in forging, smelting, precision casting, heat treatment, welding, pipe bending and other industrial fields.

Working Principle

12-pulse is a static variable frequency medium frequency power supply as the rectifier power supply of one-to-two medium frequency furnace. It uses thyristor components to convert the industrial frequency three-phase AC power supply into medium frequency single-phase AC power supply. It is mainly used in induction heating, induction melting and other occasions that require medium frequency furnace power supply.

Induction heating relies on the induction coil to transfer electrical energy to the metal to be heated, and then the electrical energy is converted into heat energy inside the metal. The induction coil is not in direct contact with the heated metal, and the energy is transferred through electromagnetic induction. It should also be pointed out that the principle of induction heating is the same as the principle of generating eddy currents and causing heating in general electrical equipment. The difference is that eddy currents are harmful in general electrical equipment, while induction heating uses eddy currents for heating. Because it has a series of advantages such as high overall efficiency, light weight, low noise, fast start and stop, no impact on the power grid, automatic frequency tracking of load parameter changes, and convenient power regulation, it is gradually replacing medium frequency generator sets.

Application

✅ Optimize large-scale metal melting

For 5+ ton steel scrap furnaces & copper alloy holding baths

✅ Power precision casting lines

Automotive/aerospace components with strict tolerance control

✅ Ensure grid compliance in eco-zones

Plants requiring IEEE 519/EN 61000-3-6 THDi compliance

✅ Sustain heavy-cycle operations

24/7 foundries with frequent cold starts

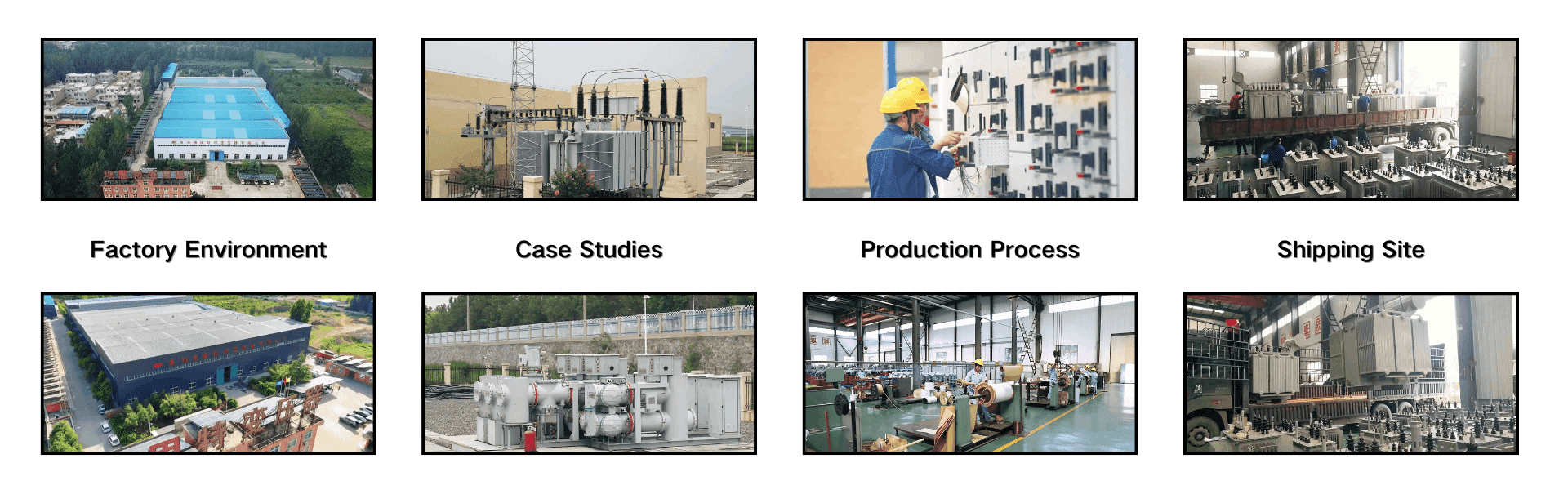

Our Factory

Our Team

Sale Cases

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China