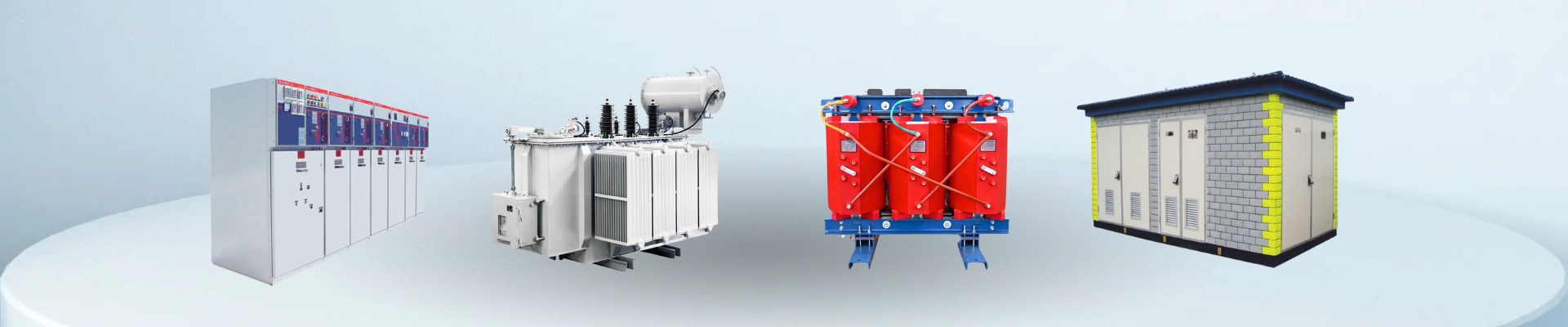

Welcome to the official website of Luoyang AISITE Transformer Co., LTD

YBM Box Substation - Combined Box Substation

The MDS pre-fabricated indoor/outdoor substation is delivered fully assembled in a single-lift operation, direct to site, and with its compact size, minimizes the space needed for installation. It is ideal for environmentally sensitive locations.

keyword:

YBM Box Substation - Combined Box Substation

Category:

DESCRIPTION

Product Introduction

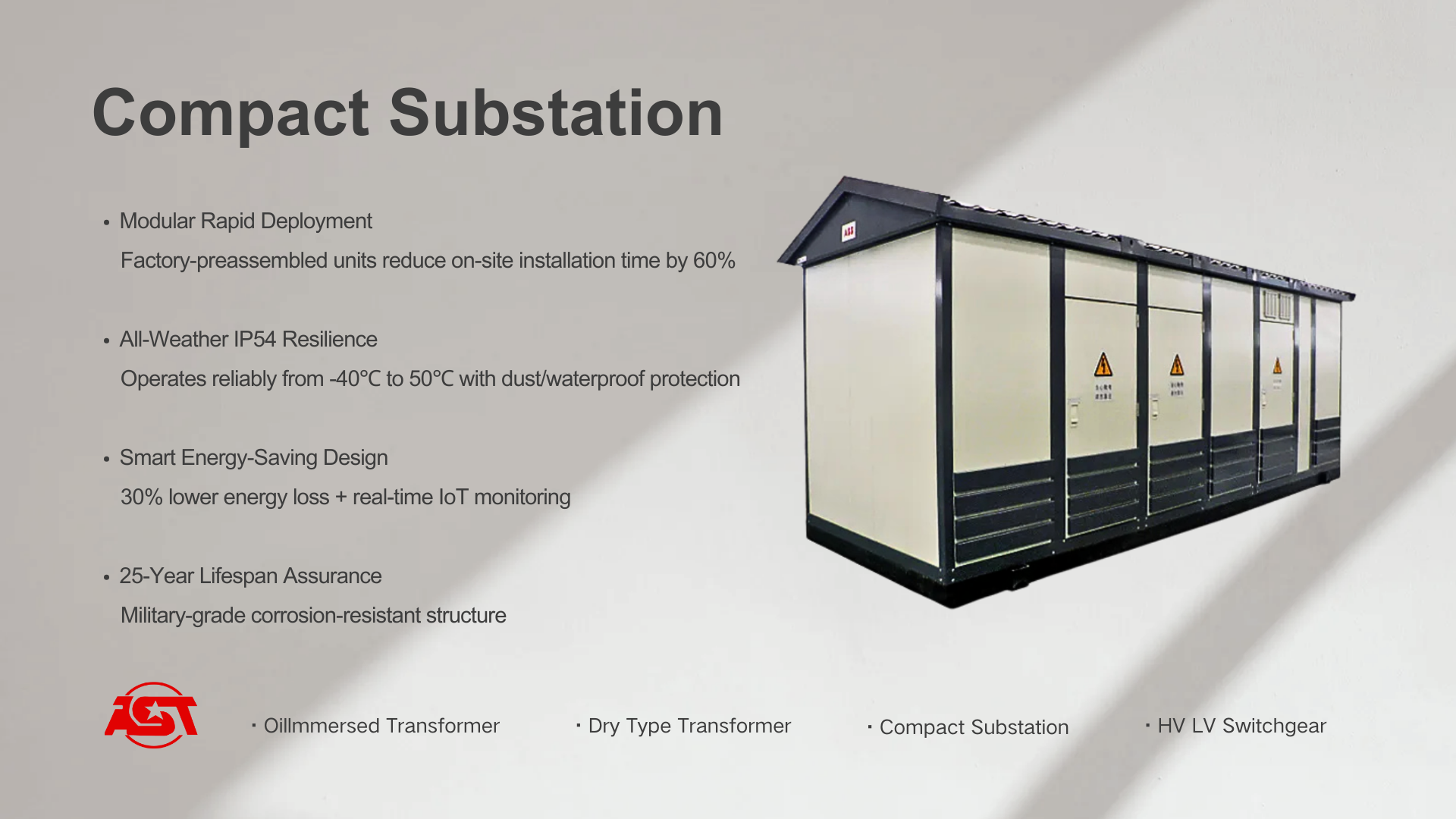

MDS prefabricated indoor/outdoor substation is a modular, integrated, intelligent power equipment solution designed for rapid deployment, efficient operation and maintenance, and flexible adaptation to different scenarios. Its core feature is to prefabricate and assemble the primary equipment (such as transformers, switchgear) and secondary equipment (such as protection and monitoring systems) of traditional substations in the factory to form standardized modules, which are then transported to the site for rapid installation, greatly shortening the construction period and improving reliability.

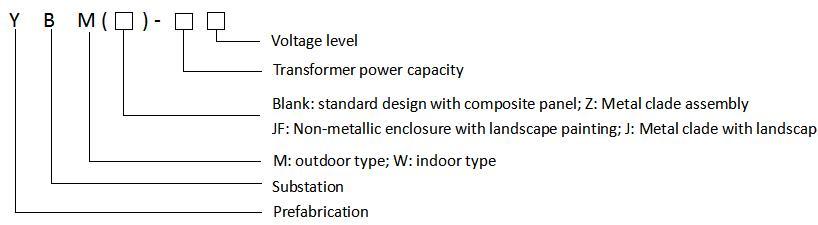

Code and implication

Features of MDS prefabricated substation

Modular design

➩Adopting the "prefabricated cabin" structure, high and low voltage distribution equipment, transformers, monitoring systems, etc. are integrated in a closed box, supporting indoor or outdoor installation.

➩Modules are connected through standardized interfaces to support on-demand expansion (such as capacity increase, new functional modules).

Environmental adaptability

➩

➩

Intelligent operation and maintenance

Integrated intelligent monitoring system (SCADA), real-time monitoring of temperature, humidity, current, voltage and other parameters.

Support remote fault diagnosis, energy efficiency analysis and automatic alarm, reducing manual inspection costs.

Quick deployment

The factory prefabrication rate is more than 90%, and only basic construction and module splicing are required on site, and the construction period is shortened by 50%-70% compared with traditional substations.

MDS Prefabricated VS Traditional Substations

| MDS Prefabricated Substation | Traditional Substation | |

| Construction Time | 2-4 months(factory pre-assembly) | 6-12 months(on-site civil works) |

| Footprint | Compact modular design, 30-50% space-saving | Large equipment rooms & cable trenches |

| Operational Efficiency | Smart monitoring & remote management | Manual inspections & delayed response |

| Scalability | Modular expansion without downtime | Complex retrofitting requiring shutdowns |

Application

Urban distribution network

Renovation of old substations and power supply for commercial complexes.

New energy field

Photovoltaic power stations, wind farm booster stations, electric vehicle charging stations.

Industry and infrastructure

Temporary power supply for industrial parks, data centers, and rail transit.

Emergency power

Disaster reconstruction, temporary event power supply (such as events, exhibitions)

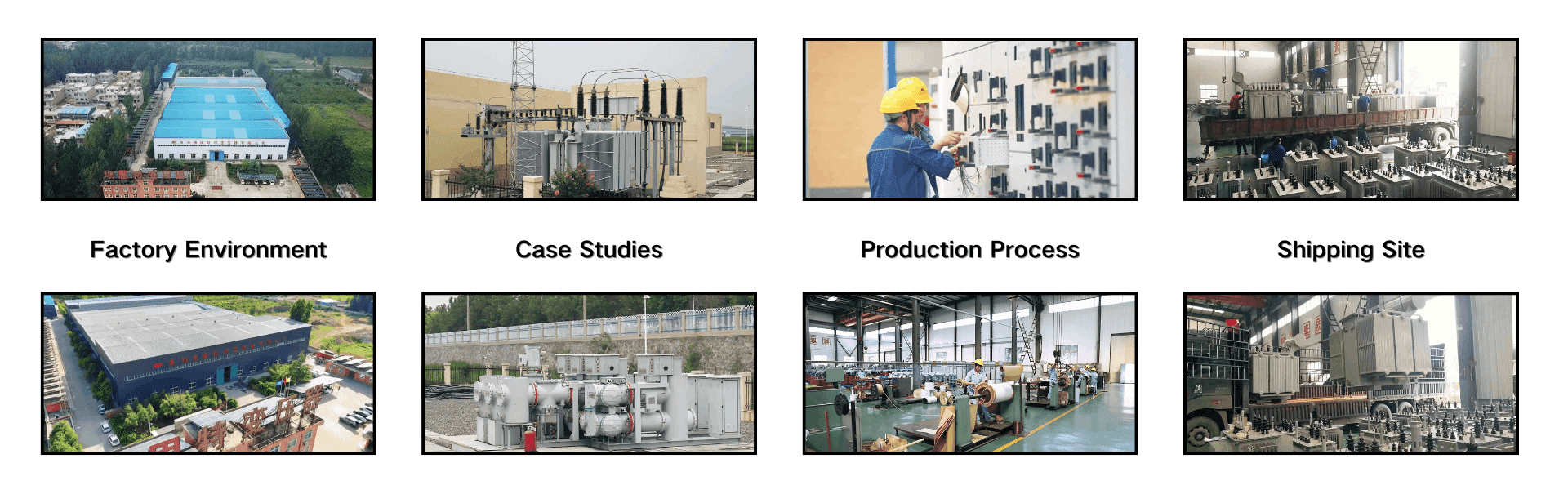

Our Factory

Sale Cases

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China