Welcome to the official website of Luoyang AISITE Transformer Co., LTD

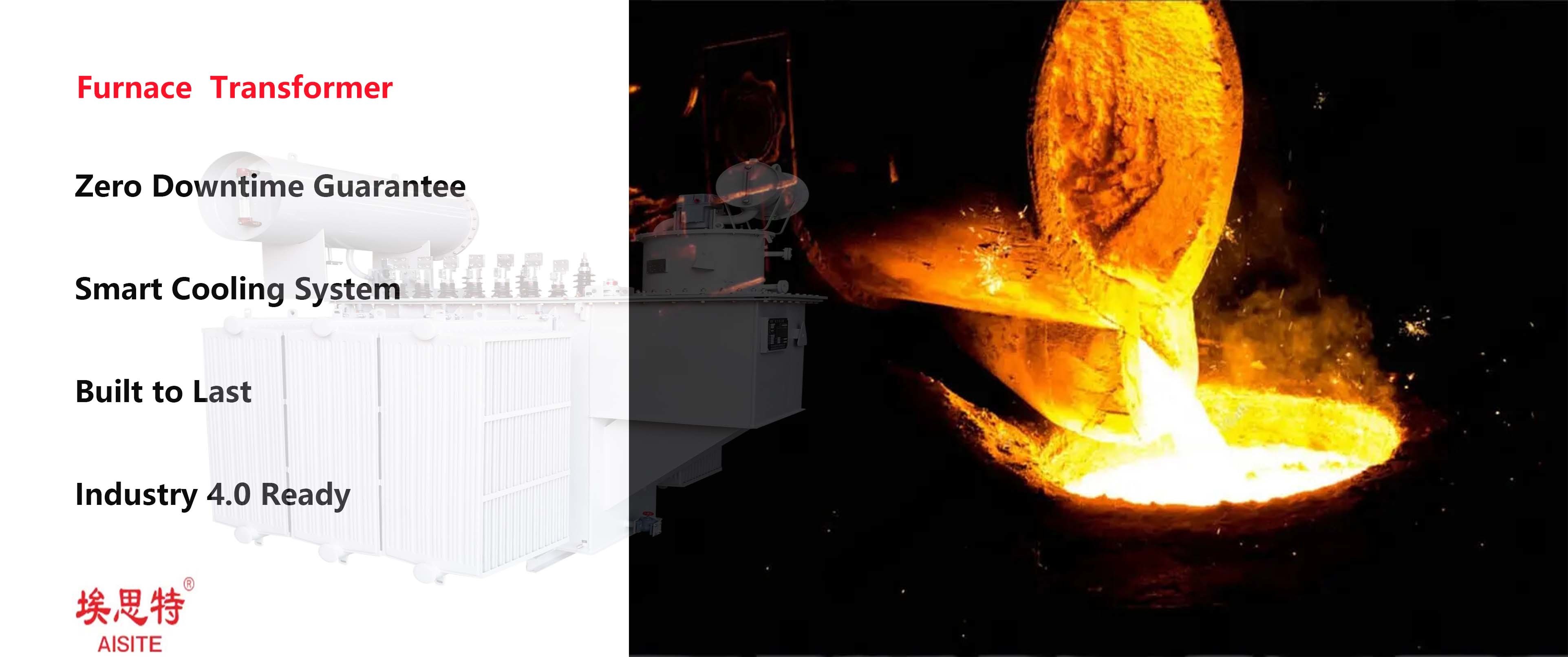

Electric Furnace Transformer

Specially designed for industrial smelting (arc furnace/submerged arc furnace), it adopts low loss design and H-class insulation system, and has impedance and short-circuit resistance.

keyword:

Electric Furnace Transformer

Category:

DESCRIPTION

Product Introduction

The electric furnace transformer is the core power supply device for industrial smelting equipment such as electric arc furnaces and resistance furnaces, and is designed for high-load continuous operation conditions. By converting the high-voltage power of the power grid into low voltage and high current (50-1500V/tens of thousands of amperes) suitable for electric furnace operation, the smelting process is ensured to operate stably. The product adopts a modular insulation system and forced cooling technology, which meets the stringent working conditions of metal smelting (steel/copper/aluminum/alloy) and chemical industries.

Features

High efficiency and energy saving

▸ Stepped laminated core with low-loss silicon steel sheet, no-load loss reduced by 15%-25%

▸ Optimized electromagnetic structure design, rated load efficiency reaches 98.5%-99.2%

Stable and durable

▸ H-class insulation material + vacuum pressure impregnation process, allowing continuous operation at 180°C

▸ Passed IEC 60076 short-circuit withstand test, short-circuit impedance deviation ≤5%

Intelligent monitoring

▸ Equipped with temperature/vibration sensor, supports Modbus/RS485 remote communication

▸ Three-level overload protection (150% 60s / 200% 10s / 250% 3s)

Flexible adaptation

▸ Voltage range: 10kV-220kV | Capacity range: 2000kVA-120MVA

▸ Voltage regulation mode: no excitation voltage regulation (±5%) / On-load voltage regulation (±10×1.25%)

Working Principle

The electric furnace transformer is the power transformer of the steelmaking electric arc furnace. The capacity of the electric furnace transformer is configured according to the size of the electric arc furnace and the smelting process. It meets the requirements of the smelting process through voltage regulation. The voltage regulation method is divided into two types: on-load voltage regulation and off-excitation voltage regulation. Large electric furnace transformers with on-load voltage regulation do not have series reactors, and the structural forms of small and medium-sized electric furnace transformers with off-excitation voltage regulation can be divided into two types: with series reactors and without reactors. These two structures can change the impedance at the highest two voltages. The former changes the impedance by the input and removal of the series reactor. The latter changes the winding impedance by changing the connection method of the high-voltage winding of the electric furnace transformer itself.

Application

▸Ferrous Metallurgy: Steelmaking arc furnaces, submerged arc furnaces for ferroalloys

▸ Non-ferrous Smelting: Core-type induction furnaces for copper/aluminum/zinc

▸ Advanced Materials: Graphitization furnaces, silicon carbide crystallization furnaces

▸ Chemical Processing: Calcium carbide furnaces, phosphorus electric furnaces

Production Process

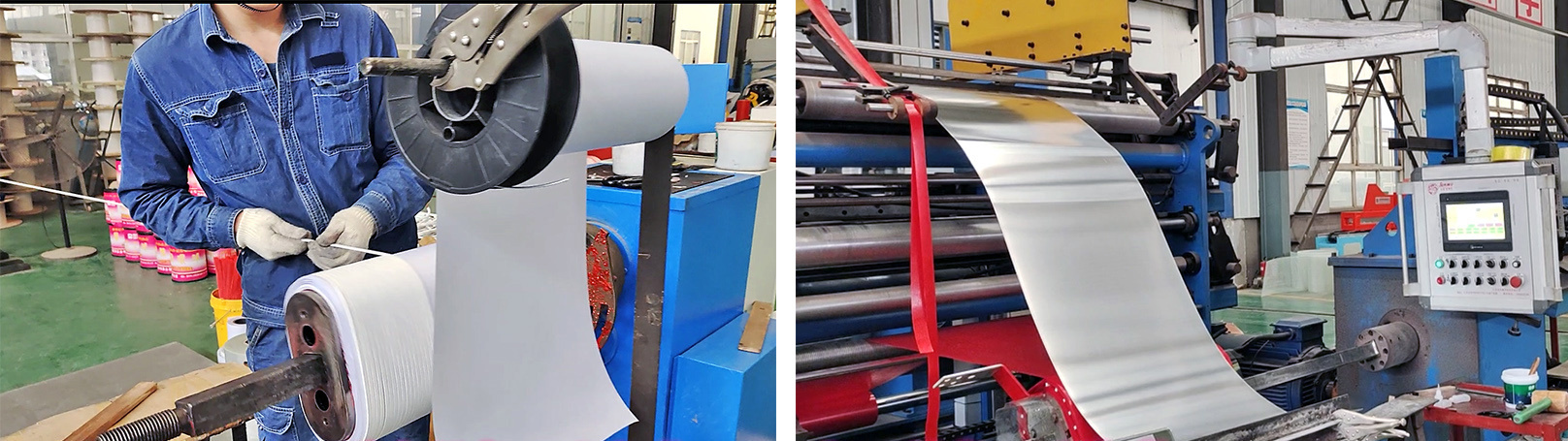

1.Core processing

The core is the core of the transformer. Its function is to conduct magnetism and transmit electrical energy. During the production process, the core will be assembled according to the requirements of different types of transformers. The core sheets are precisely cut and stacked to ensure the stability of its shape and structure. The assembled core will be sent to the next winding process.

2.Winding manufacturing and installation

Winding is an important part of oil-immersed power transformers, usually divided into high-voltage winding and low-voltage winding. During the manufacturing process, the winding wire is wound around the core at a specific position by mechanical equipment to ensure that it can efficiently transmit current. At this stage, the insulation of the winding is crucial, so each step needs to be strictly controlled.

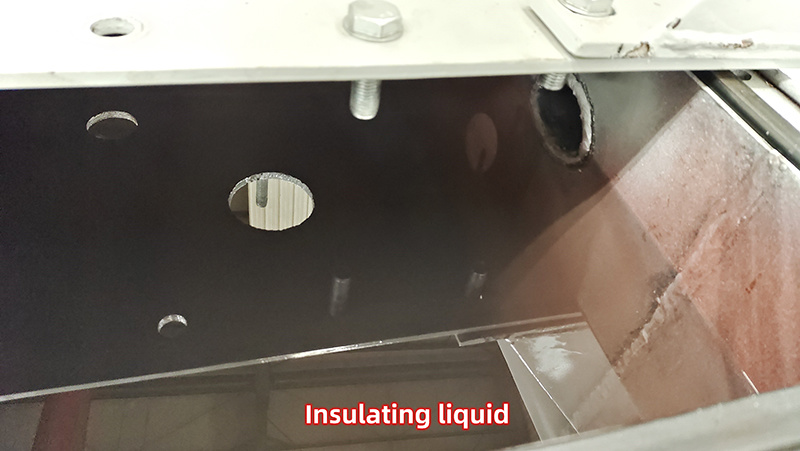

3.Insulating liquids

The layer insulation is adapted to the alternating voltage strain that occurs in daily operation. Large-scale oil channels are provided to ensure sufficient cooling of the windings and to avoid hot spots. All leads are short-circuit-proof and surge-proof, contributing to the high reliability of thetransformer – and to an above-average service life.

4.Tank & Cooling

Whether during transport or operation, the tank must remain sealed tight under mechanical stress and regardless of wind or weather. Corrosion protection is especially important. The surface is sandblasted and then multicoated. Upon request, hot-dip galvanization can provide even better protection.

5.Final assembly

The transformer’s core-and-coil assembly consists of the core, windings, and connecting cables. High-quality drying and quick filling with insulation oil play a key role in extending the transformer’s service life.Aisite employs the latest techniques. For example, in vacuum low-frequency plants (LFH – low-frequency heating), the process of drying the solid insulation is combined with vacuum drying of the windings through low-frequency heating. The active part is heated by applying low-frequency current (< 1 Hz) to the high-voltage windings with the low-voltage windings short-circuited. While still in the plant, transformers are filled with preheated insulation liquid which is absorbed by the insulation material, thus preventing the intake of oxygen.

Our Factory

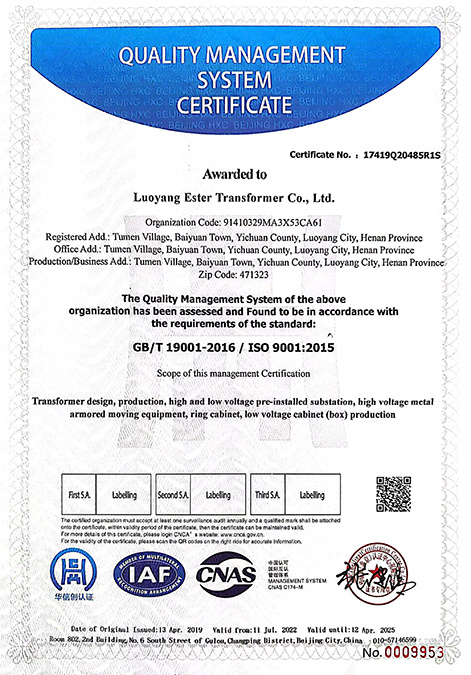

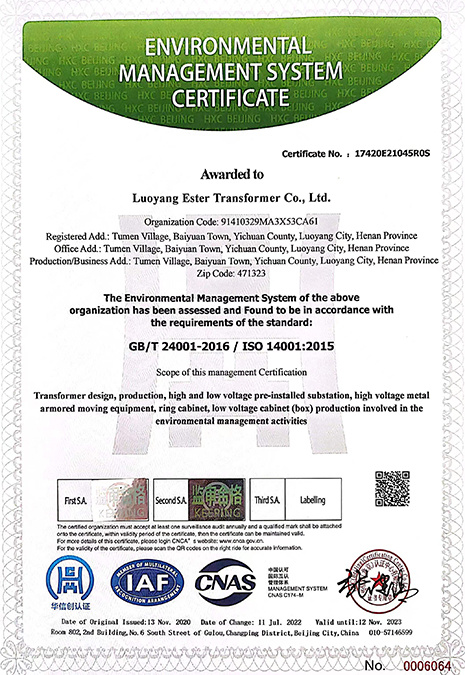

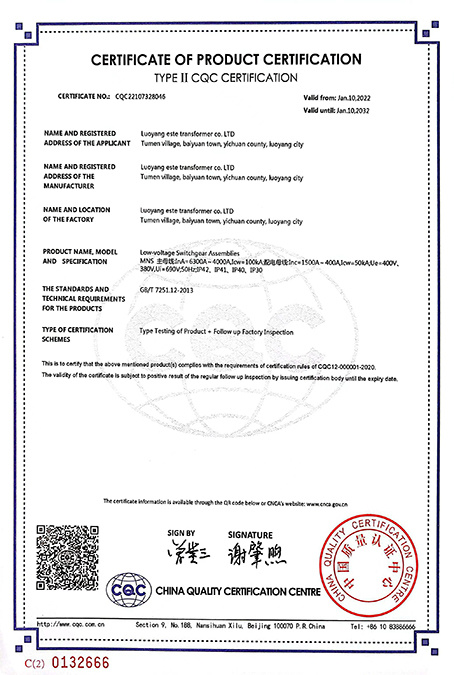

Certificate

Our Team

Sale Cases

Previous page

Next page

Previous page

Next page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China