Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Induction Furnace Transformers

Induction furnace transformers are power equipment specially designed to adapt to extremely harsh working conditions such as severe fluctuations, high currents, and high harmonic content. Their core features are high short-circuit impedance, strong mechanical structure, low-voltage and high-current windings, and efficient cooling systems.

keyword:

Induction Furnace Transformers

Category:

DESCRIPTION

Product Introduction

The induction furnace transformer is the core power supply equipment of the induction heating system. It converts the high-voltage power of the power grid into medium-frequency/power-frequency low-voltage and high-current output, providing precise electromagnetic energy for the induction furnace coil. It is specially used in high-temperature industrial scenarios such as metal smelting (steel, copper, aluminum, etc.), heat treatment, forging heating, etc.

Technical Specification

| Rated Capacity | 500kVA ~ 40MVA |

| Primary Voltage | 6 kV, 10 kV, 33 kV, up to 35 kV(customizable) |

| Secondary Voltage | 200V ~ 3000 V (low voltage, high current) |

| Frequency Range | 50/60 Hz (Power Frequency) or 50-250 Hz (Medium Frequency) |

| Insulation Class | Class F / Class H(selectable) |

| Cooling Methods | ONAN (oil-cooled) / AFWF (forced-air cooled) |

| Protection Rating | IP54 / IP55 (weather-resistant for outdoor use) |

Note: Customizable configuration based on furnace power, frequency requirements, and installation environment.

Features

High Efficiency & Energy Savings

▸ ≥30% lower no-load losses with low-loss silicon steel cores & optimized winding design

▸ Achieves up to 98% load efficiency through precise voltage matching, reducing energy waste

▸ 15% lower total energy consumption vs. industry standards

Uncompromising Reliability

▸ Class H insulation + forced-air/oil-cooling withstands continuous high-temp/high-load operation

▸ Short-circuit resistant construction with multi-protection (overcurrent/overheating/surge)

▸ ≥20-year operational lifespan

Adaptable Design

▸ Customizable specs (0.5-40MVA, ≤35kV primary, 200-3000V secondary)

▸ Compatible with MF/LF power sources & series/parallel resonant furnaces

▸ Supports global voltage standards

Eco-Friendly & Quiet

▸ Full-enclosure noise reduction design (≤65 dB(A) operational sound)

▸ Complies with IEC/IEEE/GB standards & EU CE/RoHS directives

Production Process

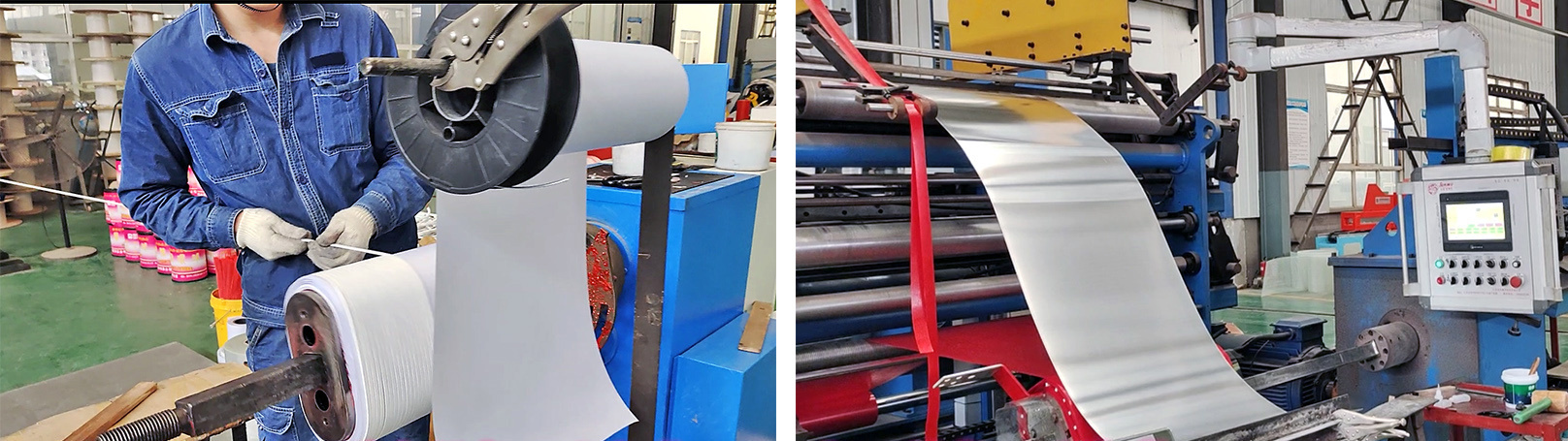

1.Core processing

The core is the core of the transformer. Its function is to conduct magnetism and transmit electrical energy. During the production process, the core will be assembled according to the requirements of different types of transformers. The core sheets are precisely cut and stacked to ensure the stability of its shape and structure. The assembled core will be sent to the next winding process.

2.Winding manufacturing and installation

Winding is an important part of oil-immersed power transformers, usually divided into high-voltage winding and low-voltage winding. During the manufacturing process, the winding wire is wound around the core at a specific position by mechanical equipment to ensure that it can efficiently transmit current. At this stage, the insulation of the winding is crucial, so each step needs to be strictly controlled.

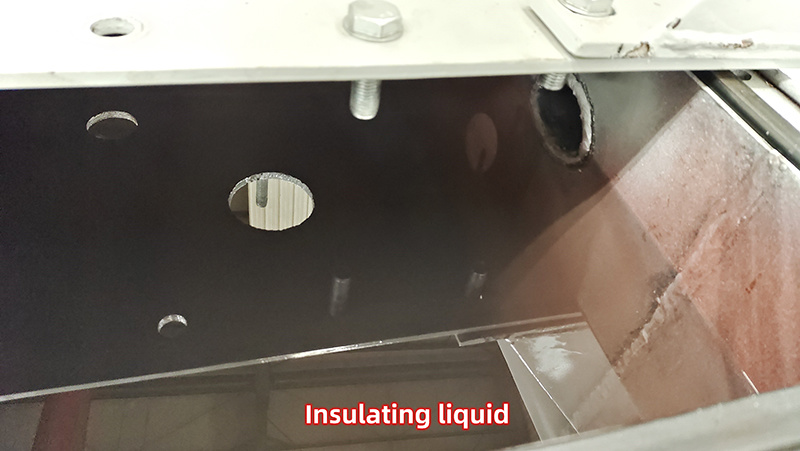

3.Insulating liquids

The layer insulation is adapted to the alternating voltage strain that occurs in daily operation. Large-scale oil channels are provided to ensure sufficient cooling of the windings and to avoid hot spots. All leads are short-circuit-proof and surge-proof, contributing to the high reliability of thetransformer – and to an above-average service life.

4.Tank & Cooling

Whether during transport or operation, the tank must remain sealed tight under mechanical stress and regardless of wind or weather. Corrosion protection is especially important. The surface is sandblasted and then multicoated. Upon request, hot-dip galvanization can provide even better protection.

5.Final assembly

The transformer’s core-and-coil assembly consists of the core, windings, and connecting cables. High-quality drying and quick filling with insulation oil play a key role in extending the transformer’s service life.Aisite employs the latest techniques. For example, in vacuum low-frequency plants (LFH – low-frequency heating), the process of drying the solid insulation is combined with vacuum drying of the windings through low-frequency heating. The active part is heated by applying low-frequency current (< 1 Hz) to the high-voltage windings with the low-voltage windings short-circuited. While still in the plant, transformers are filled with preheated insulation liquid which is absorbed by the insulation material, thus preventing the intake of oxygen.

Application

Metal Melting

→ Scrap steel/alloy steel melting → Non-ferrous metal refining (copper, aluminum, etc.) → Precious metal recovery

Heat Treatment Processing

→ Surface hardening of shafts/gears → Through-heating for forging plates → Online annealing of pipes

Specialty Materials Manufacturing

→ Monocrystalline silicon/germanium growth heating → Superalloy melting & casting → Vacuum induction melting (VIM)

Green Energy Industries

→ Solar-grade silicon purification → Sintering for Li-ion battery materials → Heat treatment of wind power components

Our Factory

AISITE Team

Rich Production Experience

With 15-year experience of production and sales, our transformers have been successfully exported to over 50 countries and regions, including Brazil, Tanzania, South Africa, etc.

Full Life-Cycle Support Service

We provide comprehensive technical support at ever stage of operation of your purchased equipment.

Professional Sales Team

Our globally-experienced sales engineers provide tailored power solutions and precise technical guidance, ensuring optional project fit for your specific requirements.

Pursue Innovation and Excellence in Serving Customers

Our technical and sales team are committed to providing customized solutions with cutting-edge technology that solve the toughest challenges facing electricity supply and meet the most stringent needs defined by the industry.

Sale Cases

Previous page

Previous page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China