Welcome to the official website of Luoyang AISITE Transformer Co., LTD

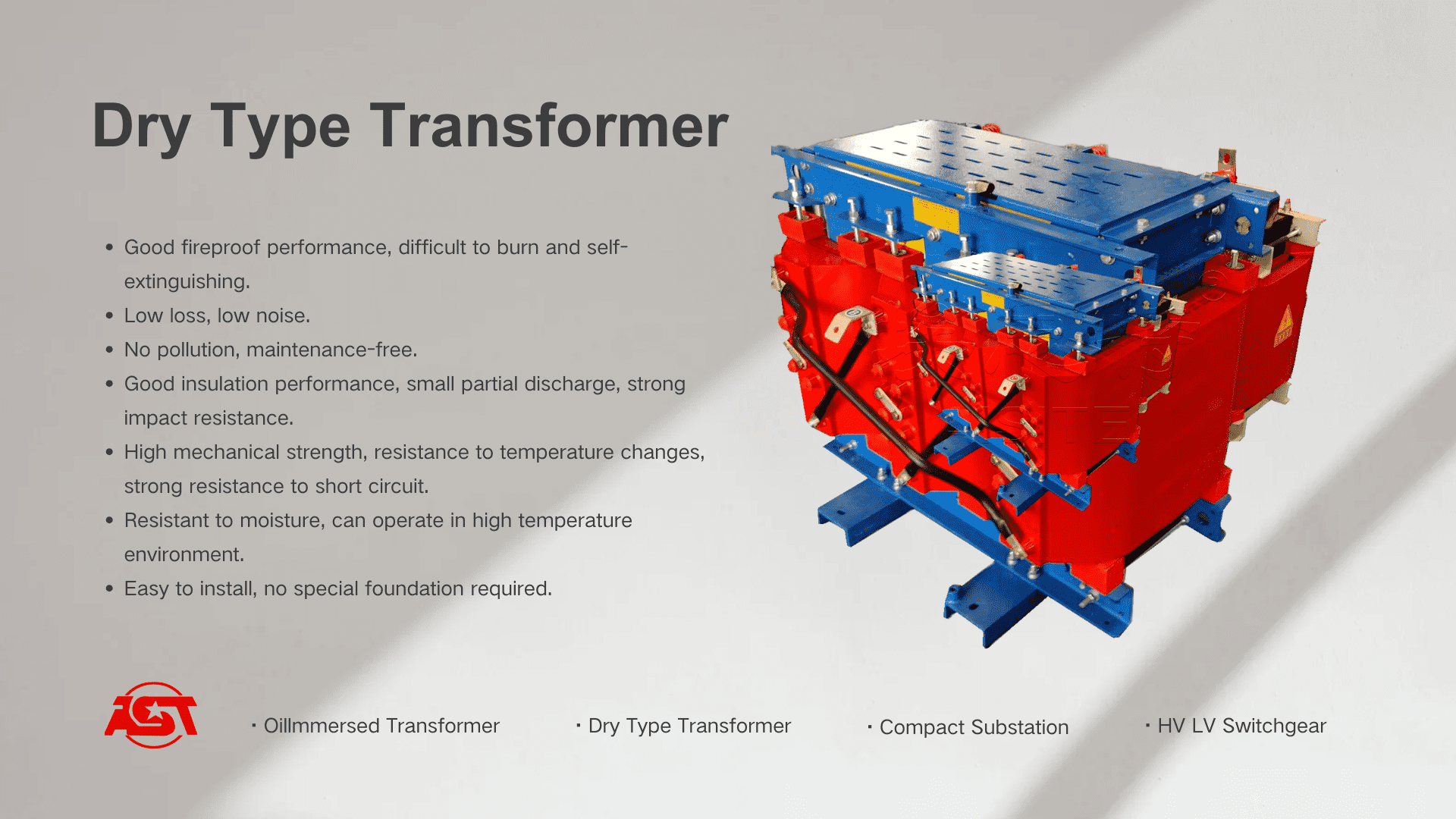

35KV Dry type transformer

AISITE 35kV three-phase dry type transformers are made with a magnetic core from laminated grain-oriented silicon steel. Additionally, HV winding can also be wound from insulated by an inter-layer film, pre-impregnated with heat-activated epoxy resin. The ends of the windings are protected and insulated using Class F materials.

keyword:

35KV Dry type transformer

Category:

DESCRIPTION

Product Introduction

AISITE 35kV dry type transformers are made with a magnetic core from laminated grain-oriented silicon steel. Additionally, HV winding can also be wound from insulated by an inter-layer film, pre-impregnated with heat-activated epoxy resin. The ends of the windings are protected and insulated using Class F materials. With outstanding resistance to harsh industrial atmospheres, excellent dielectric withstand and very good resistance to short-circuit conditions are ideal for industrial and commercial use.

Features

1.High safety performance: Dry-type transformers are flame-retardant, fire-proof, explosion-proof, and pollution-free, and can be safely installed directly at the load center.

2.Low maintenance cost: The dry type transformer is maintenance-free(No need to regularly change insulating oil or deal with oil contamination), and the comprehensive operating cost is significantly reduced.

3. Good moisture resistance: It can still operate normally in a 100% humidity environment, and can be put into use quickly without pre-drying after shutdown.

4.Efficient heat dissipation capacity: It has strong heat dissipation capacity and can operate at 150% of the rated load even under forced air cooling conditions.

5.Reliable temperature protection: Equipped with a complete temperature protection control system, it provides solid protection for the safe operation of the transformer.

6.Compact size and light weight: Dry-type transformers are small in size, light in weight, occupy less space, and have relatively low installation costs.

Technical Parameters

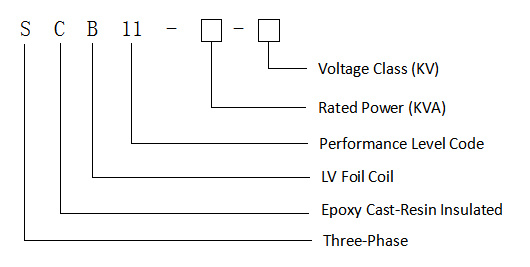

Code and implication

SCB11series 35KV cast resin transformer (dry type transformer)

Model | Rated power | Rated primary voltage | Tapping | Rated secondary voltage | Vector group | No-load losses | Load losses | No-load current | Rated impedance |

SCB11-50 | 50 | 35 | ±2×2.5 | 0.4 | Yyn0 | 450 | 1420 | 2.3 | 6.0 |

SCB11-100 | 100 | 35 | ±2×2.5 | 0.4 | Yyn0 | 630 | 2090 | 2.0 | 6.0 |

SCB11-160 | 160 | 35 | ±2×2.5 | 0.4 | Yyn0 | 790 | 2810 | 1.5 | 6.0 |

SCB11-200 | 200 | 35 | ±2×2.5 | 0.4 | Yyn0 | 880 | 3320 | 1.5 | 6.0 |

SCB11-250 | 250 | 35 | ±2×2.5 | 0.4 | Yyn0 | 990 | 3800 | 1.3 | 6.0 |

SCB11-315 | 315 | 35 | ±2×2.5 | 0.4 | Yyn0 | 1170 | 4510 | 1.3 | 6.0 |

SCB11-400 | 400 | 35 | ±2×2.5 | 0.4 | Yyn0 | 1370 | 5410 | 1.1 | 6.0 |

SCB11-500 | 500 | 35 | ±2×2.5 | 0.4 | Yyn0 | 1620 | 6650 | 1.1 | 6.0 |

SCB11-630 | 630 | 35 | ±2×2.5 | 0.4 | Yyn0 | 1860 | 7690 | 1.0 | 6.0 |

SCB11-800 | 800 | 35 | ±2×2.5 | 0.4 | Yyn0 | 2160 | 9120 | 1.0 | 6.0 |

SCB11-1000 | 1000 | 35 | ±2×2.5 | 0.4 | Yyn0 | 2430 | 1040 | 0.75 | 6.0 |

SCB11-1250 | 1250 | 35 | ±2×2.5 | 0.4 | Yyn0 | 2830 | 1270 | 0.75 | 6.0 |

SCB11-1600 | 1600 | 35 | ±2×2.5 | 0.4 | Yyn0 | 3240 | 1540 | 0.75 | 6.0 |

SCB11-2000 | 2000 | 35 | ±2×2.5 | 0.4 | Yyn0 | 3820 | 1820 | 0.75 | 6.0 |

SCB11-2500 | 2500 | 35 | ±2×2.5 | 0.4 | Yyn0 | 4450 | 2180 | 0.75 | 6.0 |

For more details, download at once.AISITE-PRODUCT SELECTION GUIDE..pdf

Application Scenarios

Commercial buildings: offices, shopping malls (indoor installation, low explosion risk)

Critical facilities: hospitals, schools (*low noise operation, ≤75dB, low environmental impact*)

Industrial sites: mining, chemical processing (corrosion-resistant design for high humidity areas)

Renewable energy: solar/wind installations (sand/salt spray resistance for coastal/arid areas)

Infrastructure: subway systems, ports (small footprint, low maintenance requirements)

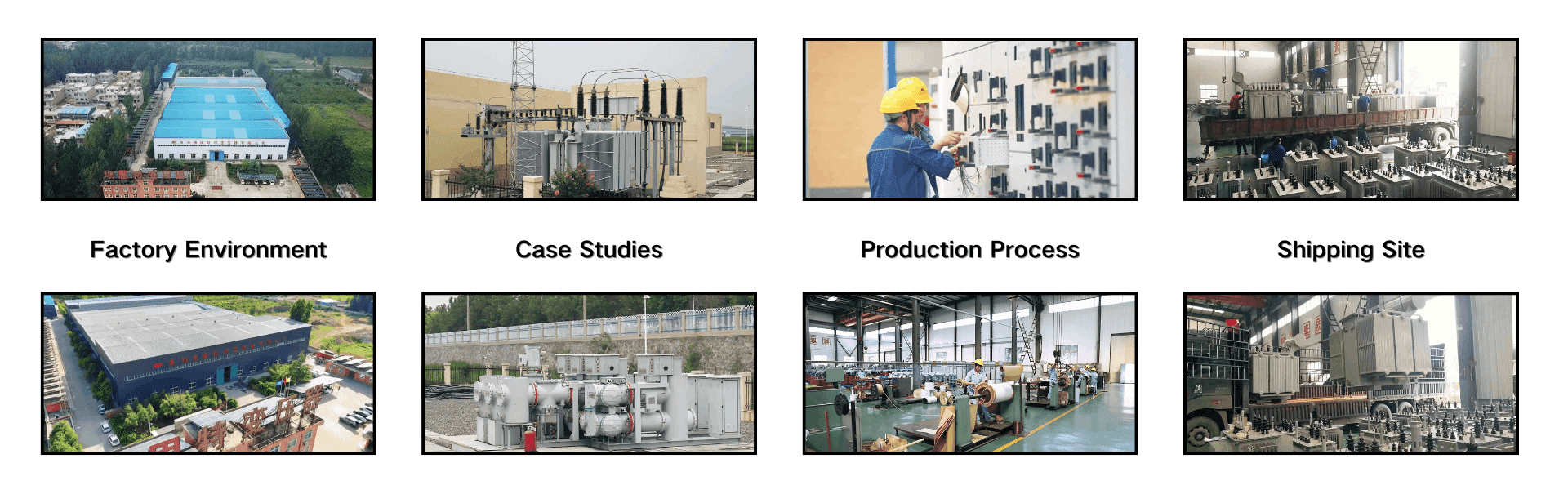

Production Process

Our Factory

FAQ

Q1: Safer for indoor use than oil-filled transformers?

Yes. No flammable oil, self-extinguishing resin (IEC 60076-11), lower fire risk.

Q2: Maintenance frequency?

Daily inspection: once a week, check the transformer's appearance, temperature, noise, etc.

Monthly inspection: Carry out once a month to check the insulation resistance, grounding resistance, etc.

Q3: Maximum operating temperature?

Rated for 40℃ ambient. At 50℃: ≈ 90% load capacity. Cooling kits available.

Q4: Suitable for humid/coastal sites?

Yes. IP54 protection >95% humidity. Anti-corrosion coating for salt air.

Q5: Space needed for installation?

30% smaller than oil types. Minimum 500mm clearance from walls (NFPA 70).

Package

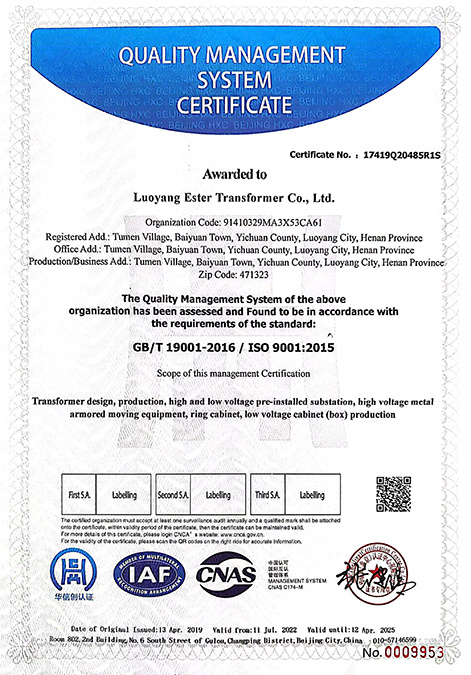

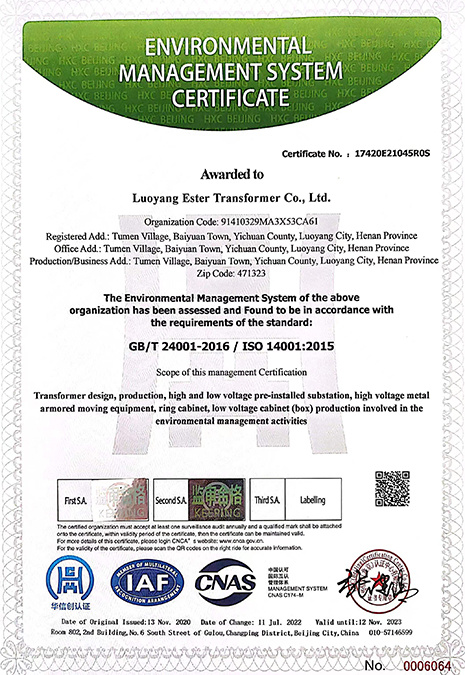

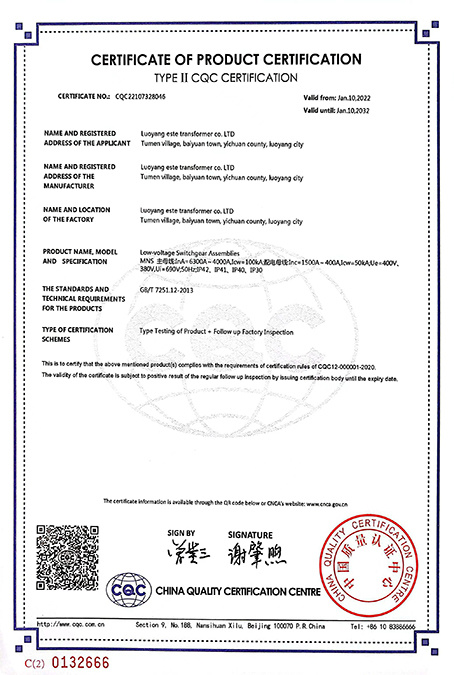

Certificate

Our Team

Previous page

Next page

Previous page

Next page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China