Welcome to the official website of Luoyang AISITE Transformer Co., LTD

Isolation Transformer- AISITE

Isolation transformers are mainly used to convert the voltage of the input power supply to the voltage of the output power supply, while protecting the terminal equipment from power supply interference and electric shock hazards.

keyword:

Isolation Transformer- AISITE

Category:

DESCRIPTION

Product Introduction

Isolation transformers are mainly used to convert the voltage of the input power supply to the voltage of the output power supply, while protecting the terminal equipment from power supply interference and electric shock hazards.

Parameters

Input Voltage | AC 220V/380V ± 10% |

Output Voltage | 1:1 or customized ratios |

Rated Power | 100VA-5000VA |

Isolation Withstand Voltage | AC 1500V - 4000V; medical-grade ≥ 3000V |

Efficiency | ≥ 88% |

Features

A notable feature of the isolation transformer is that its output and input are completely electrically isolated, which can not only effectively filter the power supply voltage supplied by the power grid and provide pure power for electrical equipment, but also prevent the risk of electric shock that may occur due to accidental contact with live parts or insulation damage.

1. It can improve electrical safety. The isolation transformer can isolate the electrical connection between the main power supply and the load, effectively avoiding safety problems such as leakage and electric shock caused by grounding faults;

2. It can reduce electrical interference. The isolation transformer can eliminate the interference caused by the load equipment and ensure the normal operation of other electrical equipment;

3. It can improve the quality of signal transmission. The isolation transformer can convert the signal into an ordinary electrical signal, which is not affected by interference, thereby improving the quality of signal transmission;

4. It can enhance the comprehensive performance of the equipment. The isolation transformer can effectively prevent the expansion of electrical faults and improve the reliability and stability of the equipment.

Application

Medical equipment: Scenarios where leakage current must be eliminated for operating room equipment, monitors, etc.

Laboratory instruments: Precision measurement equipment must be isolated from grid interference (such as harmonics and surges).

Photovoltaic systems: Isolate photovoltaic arrays from the grid to prevent DC components from invading the AC side.

Humid environments: Power supply safety protection for places such as swimming pools and ships.

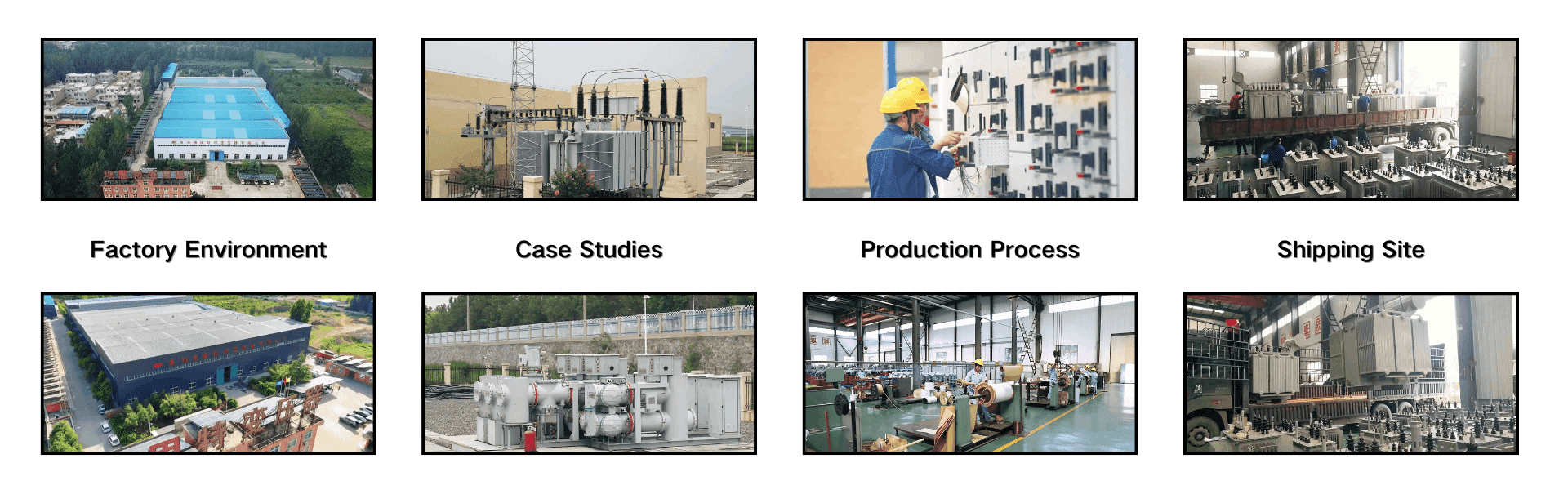

Our Factory

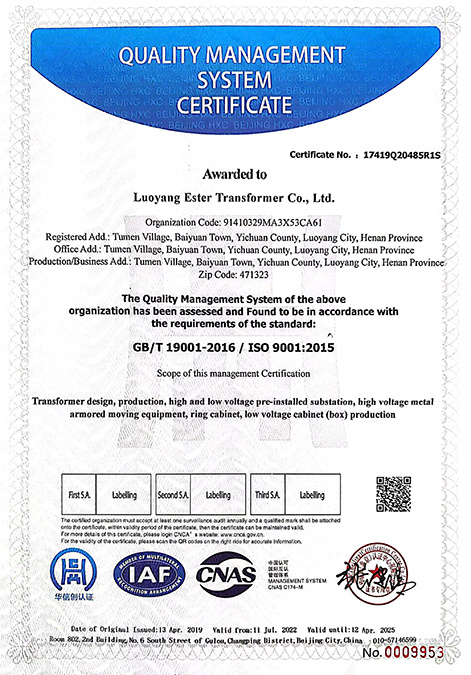

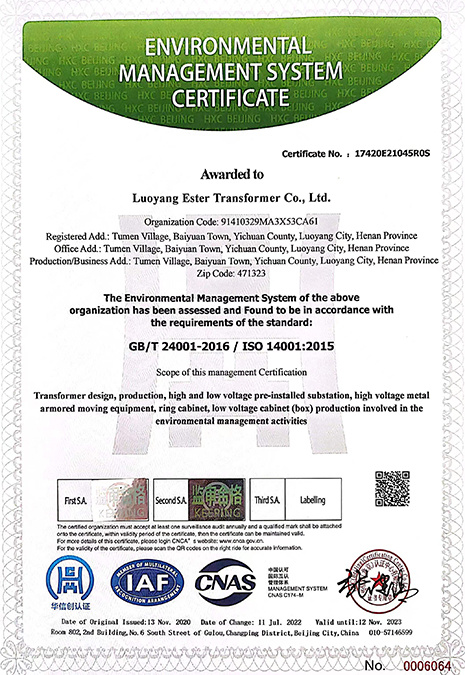

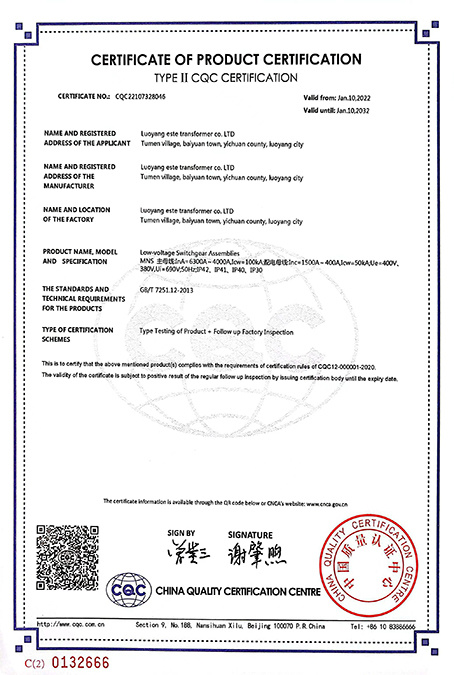

Certificate

AISITE Team

Rich Production Experience

With 15-year experience of production and sales, our transformers have been successfully exported to over 50 countries and regions, including Brazil, Tanzania, South Africa, etc.

Full Life-Cycle Support Service

We provide comprehensive technical support at ever stage of operation of your purchased equipment.

Professional Sales Team

Our globally-experienced sales engineers provide tailored power solutions and precise technical guidance, ensuring optional project fit for your specific requirements.

Pursue Innovation and Excellence in Serving Customers

Our technical and sales team are committed to providing customized solutions with cutting-edge technology that solve the toughest challenges facing electricity supply and meet the most stringent needs defined by the industry.

As a transformer manufacturer with 15-year production experience, we are able to provide reliable and high-quality isolation transformers according to your project. If any questions, feel free to contact us at any time, professional suggestions will be provided.

Previous page

Next page

Previous page

Next page

Related products

Related products

Leave a message

Factory Address:500 meters southeast of Yilong Bridge in Yichuan, Luoyang, China